Plastics are a very good fit for manufacturing and their use becomes, even more, cost-effective as volume increases.

Plastics are used to fabricate products in every major industry such as medical, automotive, electronics, housewares, etc due to their cost advantages.

Besides cost, plastics are often used in high-volume manufacturing due to the consistency of parts and the wide range of mechanical properties available through plastic material selection.

The purpose of this article is to inform you about how plastic part pricing is determined in manufacturing and how the number of cavities is driven by sales forecasts

The Basic Economics of Plastic Manufacturing

Plastic Manufacturing Setup

It’s helpful to have a basic understanding of how plastics manufacturing operates and how manufacturers charge their customers.

- A mold first needs to be installed into the molding machine, typically using an overhead crane system. The mold is installed into the molding machine by bolting the mold to the molding machine platens.

- Meanwhile, the molding machine is heating up to temperature, new plastic is loaded into the molding machine, and after reaching temperature the old plastic material in the molding machine barrel is purged and primed with new plastic.

This process of installing the mold and purging material is called “setup”. This is a separate fee that the manufacturer charges either at a fixed price or at an hourly rate.

Multiple factors contribute to mold setup costs.

- First, setup requires molding technician labor.

- Meanwhile the molding machine is offline and not producing parts during setup.

- Also, several pounds of plastic are consumed to purge the old material in the molding machine barrel.

The setup fee charged typically doesn’t provide profit to the manufacturer. The manufacturer is only seeking to cover their expenses, understanding that customers tend to be averse to a large setup charge. The manufacturer does everything possible to minimize the number of setups because they are expensive and disruptive to normal manufacturing.

Hourly Molding Machine Rate

The manufacturer will typically have an hourly rate that they charge per molding machine. However, the molding machine hourly rate doesn’t have any meaning to customers, so it is converted to cost per part. After all, that’s the key information that the customer needs to know, how much will each part cost? We’ll get into how to make that conversion later.

The hourly molding machine rate needs to cover these items:

- Electricity to run the machine,

- Staff to supervise the machine running, facilities, and other overhead.

- Sometimes the hourly molding machine rate includes the cost of plastic, but some manufacturers charge the customer for plastic separately.

The Effectiveness of Mold Cavitation

Here’s an example to illustrate the machine rates. Let’s assume an hourly molding machine rate of $130/hr. To convert this to the “cost per part” that is quoted to the customer we need to know two things:

- The cycle time of the molding process, and

- The number of cavities in the mold.

Cycle time means how long each cycle (in seconds) is required to complete all stages of the injection molding process one time. From the cycle start, injection molding includes these steps:

- Mold closing,

- Plastic injection into the mold,

- Cooling/dosing (completed in parallel, dosing is when the next plastic shot is loaded in the barrel), mold opening, and

- Part ejection from the mold.

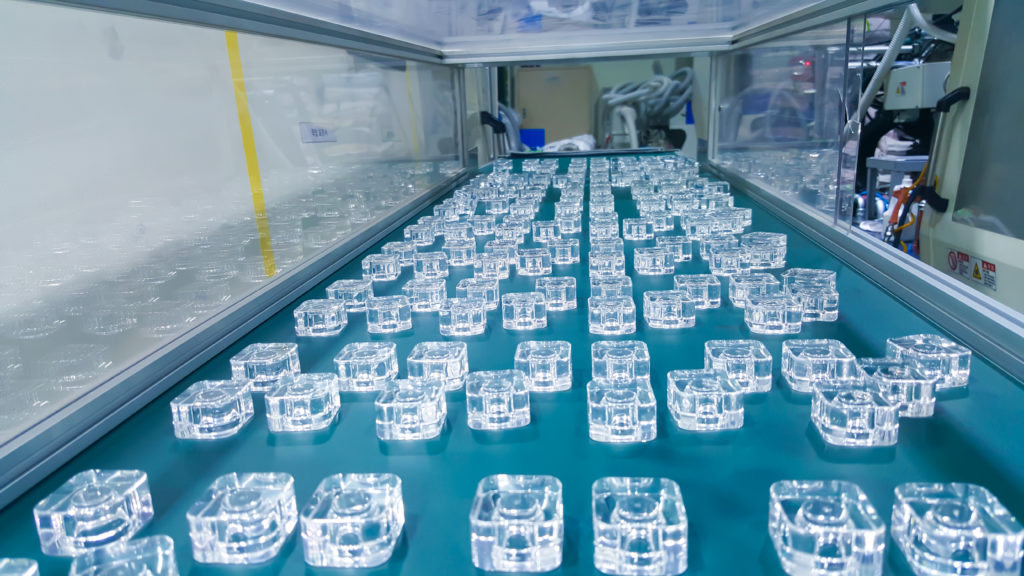

As the number of mold cavities increases, injection molding cost per part decreases. Continuing the example from above let’s assume that we are using an 8-cavity mold. This means that every time the mold opens and parts are ejected, 8 parts fall out of the mold. Let’s assume a cycle time of 30 seconds. Every 30 seconds yields 8 parts.

Step 1 – Calculate how many cycles are completed per hour by dividing 3600 seconds per hour by the cycle time.

\((\frac{3600 sph} {30 pph}) = 120 cph\)Step 2 – Calculate the number of parts per hour by multiplying the cycles per hour from step 1 by the number of mold cavities (parts per cycle)

\(120 cph * 8 ppc = 960 pph\)Step 3 – Calculate the cost per part by dividing the machine rate per hour by the number of parts per hour from step 2.

$ \((\frac{130 ph}{960 pph}) = 13.5 \) cents per part for an 8-cavity mold

Keep in mind this calculation is a simplification. The actual calculation is more complex including an assumed reject rate, less than 100% efficiency, and other factors but for the purposes of this article, the simplified calculation is sufficient to see the beneficial effect of increasing cavitation to cost.

Let’s repeat steps 2 and 3 but let’s assume a 32-cavity mold.

\(120 cph * 32 ppc = 3840 pph\)$ \((\frac{130 ph}{3840 pph}) = 3.4 \) cents per part for an 32-cavity mold

Protoshop and Mold Fabrication

Your first reaction after reviewing the calculations might be “sign me up for a 32-cavity mold or larger. I like the lower price much better”. However, selecting the number of mold cavities is not that simple. Production mold fabrication cost and lead time increase substantially with the number of cavities. It’s critical to have an accurate estimate of the sales forecast over the next 3-5 years. The number of cavities to build is determined by developing a mold fabrication strategy that will meet sales projections.

Sales forecast example:

Year 1

Year 2

Year 3

Year 4

Year 5

500,000 ea

1,000,000 ea

2,000,000 ea

3,000,000 ea

4,000,000 ea

The 8-cavity mold will provide approximately 5 million parts per year and the 32-cavity mold will provide approximately 20 million parts per year. Although the part price is attractive for the 32-cavity mold it wouldn’t make sense financially or by the capacity to invest in such a large mold. The 8-cavity mold would cover all forecasted molding needs for the first five years. Again, this is a simplification. There are scenarios where fabricating 2 ea 4-cavity molds would make sense as well.

I hope this insight into how plastic part costs are determined in manufacturing and the power of cavitation to reduce those costs has been helpful. Feel free to contact Dylann Ceriani at Protoshop (888) 316-3334 x2 or send an email to dceriani@protoshopinc.com if you have any further questions.