TABLE OF CONTENTS

- Material selection and shrinkage rate

- Molding machine

- Molding environment

- Mold fabrication equipment

- Cutting tool

You may have wondered which factors determine molded part accuracy and therefore the tolerances of the injection molded parts from both prototype and production molders. It’s a complex question that I will try to explain. Some factors that are within the molder’s control and some are not. The following factors determine molded part accuracy during mold fabrication and molding:

Material selection and shrinkage rate

Material selection and shrinkage rate is responsible for the largest contribution towards molded part accuracy. For example, polypropylene has a shrinkage range of 0.010 – 0.020 in/in, a relatively large range. The actual shrinkage rate within that range is determined by the part geometry. The challenge for mold designers is to know which shrinkage rate to apply to achieve molded parts with features that are not offset larger or smaller than nominal. Let’s assume the mold designer used a shrinkage rate of 0.013 in/in but the actual shrinkage is larger at 0.017 in/in. Let’s also assume an inspected feature on the molded part is 2” in length then the feature will be molded 0.008” larger than nominal. If the part feature needs to be within a tolerance of 0.005” then this feature will not be within tolerance and every part molded will need to be rejected. Ideally the mold designer has experience over several hundred molds with a wide variety of materials and part geometries to draw on when estimating the shrinkage to apply when designing the mold.

Molding machine

Molding machine is a factor that provides the molder some flexibility. The accuracy and repeatability of each shot as well as precise temperature control requires selection and investment in a high quality molding machine. Not all molding machines are created equally. In addition, the shot volume and clamping force of the molding machine must be selected based on the needs of the mold to be run. As a rule of thumb, the shot volume of the machine should be between 20-80% of the barrel capacity. Lower than 20% tends to create plastic residency issues with the material spending too much time in the barrel which can negatively alter material properties. Too large of a shot volume can create issues with consistency of the melted plastic. Assuming that a high quality machine of the correct size is selected, a skilled molder can adjust the molding process to provide flexibility to adjust geometry on the order of about 0.001” as needed.

Molding environment

Molding environment such as the temperature and humidity around the molding machine during molding. If the environment is not controlled part geometry can vary by up to 0.003” using the same molding process compared to a day running with ambient temperate of 75 deg F and low humidity. Therefore, it’s critical to select a molder that has a controlled environment around their molding machines. There are many molders that do not have a controlled

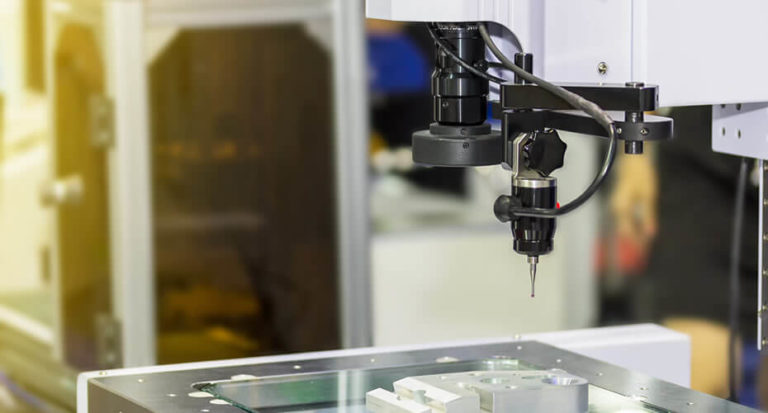

Mold fabrication equipment

Mold fabrication equipment including the milling machine, lathe, EDM (electrode discharge machining), grinding, etc. It’s important to select a molder that is using fabrication equipment with sufficient accuracy for mold fabrication. Equipment with a tolerance of 0.0001” or better is recommended. The contribution from this source is typically negligible with the selection of proper equipment.

Cutting tool

Cutting tool accuracy such as ball or end mills also typically have a negligible contribution towards molded part accuracy if the cutting tool is properly measured before machining. If properly measured, the actual tool diameter can be incorporated into the toolpaths used to fabricate the mold. This limits mold fabrication inaccuracies due to the cutter to within a tolerance of 0.0001”. While this can be difficult to confirm, select a molder that has inspection equipment in their machine shop as this is an indication that the machinists are measuring cutting tools rather than assuming the diameter when creating toolpaths.

Discussion and Conclusions

Since material selection and shrinkage are the most significant factor towards determining molded part accuracy and tolerance, they deserve further discussion. The details of material selection are the subject of a separate article since there are many factors that need to be considered. Injection molded plastics fall within two categories: amorphous and semi-crystalline. Amorphous materials include polycarbonate, ABS, HIPS, etc.

Semi-crystalline materials include polypropylene, polyethylene, etc. One of the key differences between amorphous and semi-crystalline materials is the shrinkage rate. Semi-crystalline materials typically have shrinkage rates that are 2-3 times greater than amorphous materials. We have already examined how semi-crystalline materials such as polypropylene have a relatively large range of shrinkage and how it doesn’t take a large difference between the estimated and actual shrinkage to create an inaccuracy that creates a bias in the part being either too large or too small compared to nominal that can easily exceed the tolerance. Therefore, the most part accuracy occurs by selecting an amorphous material which allows for tighter tolerances to be defined.

The estimation of shrinkage rate for the mold design can be further complicated if the material to be used contains an additive. Many times, the additive will alter the shrinkage, sometimes significantly such that it can be difficult to estimate accurately. In that case, the approach would be to run the material in an existing mold that has similar size and geometry. Measurements of the molded parts can then be used to determine the shrink rate of the material in that mold. Although the shrink rate would not be an exact estimation of material shrink rate, it is close enough for use in designing a new mold.

As we’ve discussed there are several factors which determine molded part accuracy. However, material selection along with the estimation of the shrinkage rate during mold design are by far the most significant and require the most attention.