Protoshop Offers High Quality,

Rapid Prototype Injection Molding and Mold Fabrication

Protoshop Molded Part Services

We aim to replicate production mold quality as closely as possible. Our customers are not limited by part geometry. If it can be molded, we can do it! We’ve fabricated thousands of successful prototype molds.

You’re not alone. Let our experienced plastics engineers review your part model and provide guidance which will yield prototype parts that meet your functional requirements.

What is Prototype Tooling?

The terms “tooling” and “mold” are interchangeable. Prototype tooling fills a very important need during product development of providing plastic injection molded parts. Those parts are used for testing against product requirements. Prototype tooling is typically implemented immediately following a period of development, testing and iteration using 3D printed parts. 3D printed parts are a good fit for early development since a low number of parts may be built quickly. The drawback of 3D printed parts is that larger numbers of parts are expensive and impractical. Also, testing with actual injection molded materials becomes more critical as development progresses. At that point, it’s important to fabricate a set of prototype tooling.

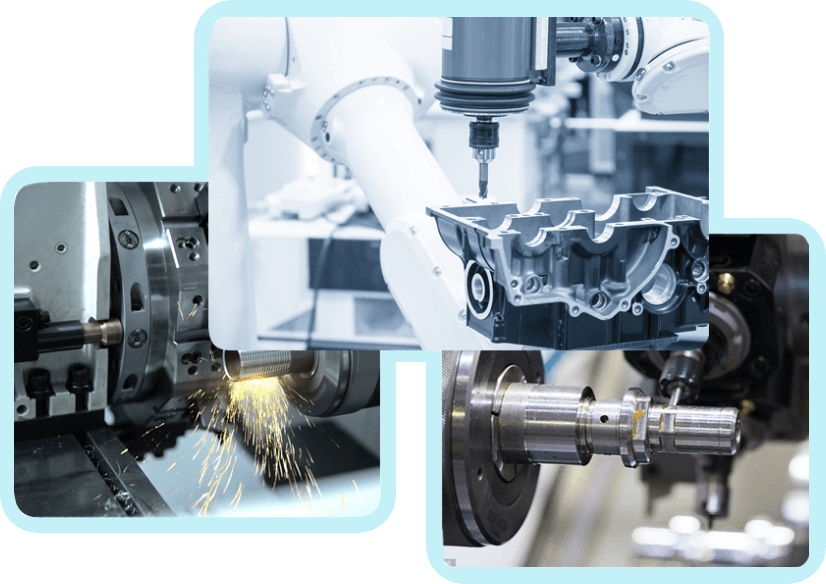

Prototype tooling is typically fabricated using CNC machining to build mold cavities in soft metal that allow for injection molding of parts in low quantities to support development. The soft metal allows molds to be fabricated and iterated quickly.

Ideally, prototype tooling yields molded parts that closely replicate production quality parts. When parts do not replicate production quality with issues such as part inconsistency or inaccuracy, it is more difficult for engineers to determine root causes during testing. This can significantly increase the time needed to complete development and transfer to manufacturing as well as lead to ongoing issues that need to be resolved when the product is on the market. Therefore, accurate prototype parts are critical to effective product development.

What You Get with Protoshop

Superior production

part quality

We strive to replicate production part quality, without sacrificing speed.

No part geometry

limitations

Frustrated by rejected part geometry from other prototype mold vendors? Complex prototyping is our specialty including unusual materials, insert injection molding, and overmolding.

Rapid mold iterations

Our molds are intended to allow for quick iterations to part geometry, typically in just 1 day.

Moldability Review

Our customers receive a complimentary moldability review of their part design where we will meet online to discuss areas that have the potential for molding defects. Personal attention ensures your part is successful the first time.

Prototype material selection assistance

There are thousands of available thermoplastic grades. It can be difficult to select the right material without extensive plastics experience. Let us help you select the right material for your application.

Large quantities of parts may be quickly molded

Several thousand parts may be provided per week from our prototype molds.

Molds are transferable

Our molds may be readily transferred to any contract manufacturer as needed.

Flexible material options

We have a variety of plastic materials in stock. We can also mold prototype parts using customer supplied materials or we can purchase new materials as needed.

How We’re Different

EXPERIENCE

Protoshop differs from other prototype molders due to the proprietary injection molding method we have created for our prototype molding. Our founders have over 25 years of medical product development experience in consumable plastic products and have designed and fabricated thousands of prototype molds.

PERSONAL SERVICE

We seek to educate and work collaboratively with our customers using online moldability review meetings where we review areas of potential molding defects in their part models and explain why those areas may be an issue. Other prototype molders only provide an automated review indicating issues found by their software. We feel that this personal interaction is critical towards ensuring that your molded parts successfully meet your needs the first time.

A SUPERIOR CUSTOMER EXPERIENCE

We have invested in creating a website that significantly improves the customer experience. Our website informs customers by email when the project status changes, so you are aware of progress up to the minute. When parts are shipped, you’ll automatically receive FedEx tracking details and inspection reports. Requests to mold additional parts and to iterate molds are quickly and easily completed on the website. The complete history of your project is always available including quotes, packing slips, inspection reports, and mold iterations that can be viewed and downloaded at any time.

How the Prototyping Process Works

Upload part model for prototype mold quote

Accept quote

Mold fabrication completed

Mold sampling (25 ea) and client review

Order prototype parts as needed

Request rapid mold iterations as needed

General Information

Lead Time

Typically 1 week, we will indicate the lead time when we provide your quote.

Maximum Part Size

Part may be up to 8″ x 6″ x4″ (200 x 150 x 100 mm)

Maximum Part Volume

Shot volume up to 6 oz (170 g)

Tolerance

Typically <0.004″ (0.1 mm).

Tolerance of 0.001″ (0.025 mm) is possible with certain materials and part geometry. Let’s discuss your application.