Injection Molding Material Selection Guide

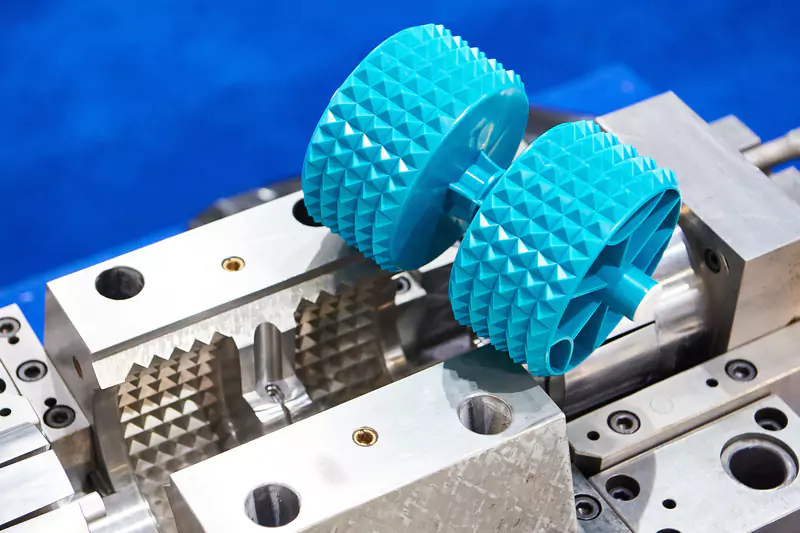

Injection molding is one of today’s most versatile and widely used manufacturing processes. Dating back to the late 19th century, this technique has evolved significantly, allowing for the creation of complex and high-quality parts across many industries. At its core, injection molding involves melting plastic materials and injecting them with high pressure into a mold, where the plastic cools and solidifies into the final part. However, the simplicity of this process needs to address the complexity and integral nature of one of the process’s main elements: material selection.

The material selected for the injection molding part directly impacts nearly every aspect of the final product, from its strength and durability to its appearance and environmental compatibility, and impacts the functionality, quality, and cost-effectiveness of the final product. Making the right choice requires a deep understanding of the properties of various plastics and how they react, not just during the molding process but also in their final application. The material chosen dictates the ease of manufacturing, cost-effectiveness, and, ultimately, the product’s success in its intended market.

Whether you’re charting new territories in product development or striving to refine your existing processes, the information here is crafted to enhance your understanding and guide your material selection journey, ensuring informed strategic choices for every project you undertake.

Understanding Material Properties in Injection Molding

Two primary types of plastics are used in injection molding: thermoplastics and thermosets. Understanding their differences and inherent properties is crucial in selecting the right material for your project.

Thermoplastics vs. Thermosets

Thermoplastics are plastics that, once molded, can be reheated and reshaped without altering their chemical structure. This property makes them highly versatile and recyclable. Common examples include polyethylene (PE), polypropylene (PP), and polystyrene (PS). Their ability to withstand multiple processing cycles without significant degradation is a valuable attribute in many applications.

Conversely, thermosets are materials that, once molded and set, cannot be remelted or reformed. During the curing process, they undergo a chemical change that creates a rigid, three-dimensional network. This transformation renders them heat resistant and structurally stable but also means they cannot be recycled like thermoplastics. Epoxy resins and phenolic plastics are typical examples of thermosets.

The Main Properties of Injection Molding Materials

When selecting a material for injection molding, several properties should be considered:

Strength

This refers to the material’s ability to withstand an applied force without yielding or breaking. High-strength materials are essential in applications where the part must bear heavy loads or resist mechanical stress.

Impact Resistance

Impact resistance is a measure of a material’s ability to absorb energy and withstand sudden impacts without fracturing. Materials with high impact resistance are crucial in products that are prone to dropping or collision.

Heat Tolerance

Heat tolerance indicates the temperature range a material can withstand without losing its structural integrity or physical properties. This is critical in products that will be exposed to high temperatures during use or in environments where thermal stability is essential.

Relating Properties to Performance Under Load

A part designed to bear weight or endure mechanical stresses must be made of a material with high strength and good impact resistance to prevent failure. Similarly, components in high-temperature environments or those subjected to thermal cycling need materials with excellent heat tolerance. For example, a car’s dashboard must endure direct sunlight and varying temperatures while supporting mounted components. A material like ABS (Acrylonitrile Butadiene Styrene), known for its strength, impact resistance, and moderate heat tolerance, would be an appropriate choice.

Navigating the Data for Informed Material Selection

Material Data Sheets (MDS) are more than just technical documents; they are a critical tool in your material selection process. Material Data Sheets provide additional detailed information about the properties and characteristics of various plastics. These properties are not just theoretical concepts but are directly linked to how well the final product will perform under the specific conditions it will encounter. Your role in this process is to balance these properties with your project’s functional requirements and constraints to ensure optimal performance and durability of the molded parts.

This section will guide you through the common data provided in these sheets, the testing methods behind the data, and how to interpret and make decisions based on this information. Additionally, we’ll explore case studies that illustrate the practical application of datasheet information in selecting materials.

Interpreting Data in Material Data Sheets

Interpreting a Material Data Sheet effectively requires an understanding of your project’s specific needs. For instance, if you are designing a part that will be exposed to high temperatures, you would prioritize materials with a high melting point and thermal stability. Similarly, for a component that needs to flex without breaking, high elongation at the break would be a desirable property.

A typical Material Data Sheet includes different types of technical data, such as

- Mechanical Properties: Including tensile strength, elongation at break, and modulus of elasticity. These variables describe the material’s ability to withstand forces.

- Thermal Properties: Information like melting point, glass transition temperature, and thermal conductivity provide insights into how the material behaves under various temperature conditions.

- Electrical Properties: Data like dielectric strength and surface resistivity are fundamental for applications where electrical insulation or conductivity is a factor.

- Chemical Resistance: This indicates how the material reacts to different chemicals for applications involving exposure to solvents or other reactive substances.

Testing Behind the Data

The data provided in an MDS is derived from standardized tests. For example, tensile strength is measured using ASTM D638, where a sample is stretched until it breaks. The melting point is determined through Differential Scanning Calorimetry (DSC) according to ASTM D3418. These standardized tests ensure consistency and reliability of the data across different materials and suppliers.

It’s important to note the conditions under which the tests were conducted, as these conditions can greatly influence the material properties. For example, a material might show different tensile strengths at varying temperatures or humidity levels.

Understanding Material Behavior in Injection Molded Parts

Strain rate and melt flow rate affect material properties. This section explores these properties, as well as discusses the implications of electrical properties and flammability based on various applications.

Strain Rate Effects on Material Properties

The strain rate, or the speed at which a material is deformed, significantly impacts its properties. For instance:

- High Strain Rates: Materials like ABS and Polycarbonate often exhibit increased ductility and impact resistance under high strain rates, making them ideal for applications like protective gear and automotive bumpers.

- Low Strain Rates: At low strain rates, some materials can experience creep, where they slowly deform under a constant load. This is a critical consideration for parts in structural applications where long-term load-bearing capacity is essential.

Significance of Melt Flow Rate (MFR)

Melt flow rate (MFR) is a measure of the ease with which a material can flow in its molten state and is crucial for determining the suitability of a material for a particular molding process.

- High MFR: Materials with a high MFR are easier to mold, suitable for intricate designs and thin-walled components. However, they may have lower mechanical strength.

- Low MFR: These materials are more challenging to mold but often result in stronger, more durable parts. They are preferred for components that require high structural integrity.

Implications of Electrical Properties

The electrical properties of materials, like dielectric strength and conductivity, are vital in many applications:

- Dielectric Strength: Materials with high dielectric strength, such as Polystyrene and Polycarbonate, are ideal for electrical insulators and components in electronic devices.

- Conductivity: Certain applications may require electrically conductive plastics, which can be achieved through additives or specific materials like certain grades of Polyamide.

Flammability Properties and Its Applications

The flammability of a material is important in applications where fire safety is a concern:

- High Flammability: Some materials, like Polystyrene, are inherently flammable and require careful consideration or additives to improve fire resistance.

- Low Flammability: Materials like ULTEM and certain grades of ABS are flame retardants, making them suitable for applications in electronics, aerospace, and public transport systems.

Long-Term Performance and Durability of Injection Molded Materials

Proper part design and material selection ensures long-term performance and durability for injection molded parts. Factors like creep resistance and continuous load capacity, as well as the impact of temperature on degradation rates, are intrinsically linked to the molecular structure of materials. This section explores these relationships and their implications for the longevity and reliability of injection-molded products.

Creep Resistance and Continuous Load Capacity

Creep Resistance

Creep is the tendency of a material to deform permanently under the influence of constant stress over time. It is particularly relevant in applications where parts are under continuous load. The molecular structure plays a pivotal role in a material’s creep resistance. For instance, materials with a higher degree of crystallinity, such as Polyethylene (PE) and Polypropylene (PP), typically exhibit lower creep under constant stress due to their tightly packed molecular chains, which provide greater resistance to movement.

Continuous Load Capacity

This refers to the ability of a material to withstand constant stress without significant degradation in its properties. Materials with strong intermolecular bonds, such as thermosetting polymers and certain high-performance thermoplastics like PEEK, tend to have higher continuous load capacities. The cross-linked molecular structure in thermosets, for example, provides a rigid framework that resists deformation under continuous load.

Temperature and Material Degradation

The relationship between temperature and the rate of material degradation is often empirical, relying on observations and testing rather than theoretical models. However, some general trends can be noted:

Arrhenius Equation

A commonly used model to describe the effect of temperature on the rate of chemical reactions is the Arrhenius Equation. It posits that for many materials, the rate of degradation doubles with every 10°C increase in temperature. This is particularly relevant for polymers, where higher temperatures can accelerate oxidation and other degradation processes.

Thermal Stability

Different materials have varying levels of thermal stability, which is influenced by their molecular structure. For example, materials with strong covalent bonds and aromatic structures, like PEEK and certain nylons, exhibit higher thermal stability and thus degrade more slowly at elevated temperatures.

Environmental Stress Cracking (ESC)

Certain plastics are susceptible to environmental stress cracking when exposed to specific chemicals at elevated temperatures. The resistance to ESC is largely dependent on the material’s molecular structure, with cross-linked polymers generally showing better resistance.

Case Studies:

Selecting Materials from Data Sheet Information

Automotive Parts

Consider the production of a car bumper. The bumper needs to be strong, impact-resistant, and able to withstand temperature fluctuations. A review of MDS might lead to the selection of High-Density Polyethylene (HDPE), known for its high impact resistance and strength, as indicated by its mechanical properties data.

Electronic Housings

In designing a housing for a handheld electronic device, factors like electrical insulation and durability are primary considerations. Polycarbonate, with its high dielectric strength and good mechanical properties, as shown in its MDS, would be an appropriate choice.

Medical Devices

For a medical device that comes in contact with various chemicals and body fluids, chemical resistance is critical. Polypropylene, with its excellent chemical resistance as shown in its MDS, alongside other favorable mechanical properties, would be a suitable material.

In each of these case studies, the decision-making process is guided by a thorough analysis of the Material Data Sheets, aligning the material properties with the specific requirements of the application.

By understanding the data provided, the testing behind it, and how to interpret this information in the context of your specific needs, you can make informed decisions that significantly impact the performance and success of your injection molded parts. Remember, the key is not just to read the data but to understand it in relation to your project’s unique requirements.

Guidelines for Material Selection in Injection Molding

This section provides a step-by-step methodology for engineers and rules of thumb for non-engineers to facilitate informed material selection.

For Engineers: Step-by-Step Guide for Applications and Methodology

- Define the Application Requirements: Begin by understanding the functional requirements of the component. Consider factors like mechanical load, operating temperature range, environmental exposure (chemicals, UV light, moisture), electrical requirements, and aesthetic considerations.

- Assess Material Properties: Evaluate potential materials based on their mechanical properties (strength, elasticity, toughness), thermal properties (heat resistance, thermal conductivity), chemical resistance, electrical properties, and any specific characteristics like biocompatibility or flame retardancy.

- Consider Manufacturing Constraints: Take into account the manufacturability of the material. Assess its flow behavior, shrinkage rates, ease of molding, and compatibility with your injection molding equipment.

- Evaluate Cost-Effectiveness: Analyze the cost of the material not just in terms of raw material cost but also considering factors like molding cycle time, energy consumption, and scrap rates. High-performance materials may offer long-term cost savings despite higher initial costs due to better durability or performance.

- Compliance and Sustainability: Ensure the material complies with industry regulations and standards. Also, consider the environmental impact, focusing on sustainability, recyclability, and life cycle assessment.

- Prototype and Test: Before finalizing the material, create prototypes and conduct tests to ensure the material meets all the application requirements under real-world conditions.

- Iterate as Needed: Based on testing feedback, iterate on your material choice or component design to optimize performance and cost.

For Non-Engineers: Rules of Thumb

- Understand the Basics: Familiarize yourself with the basic properties of common materials. For example, ABS is strong and versatile, while Polyethylene is great for its chemical resistance and flexibility.

- Identify Fundamental Requirements: Focus on the primary requirement of your part. If it needs to be strong, consider ABS or Nylon. For chemical resistance, look towards Polyethylene or Polypropylene.

- Simplify Choices: Use general categories to narrow down your options. For instance, Polycarbonate and PMMA (Acrylic) are good choices if you need a transparent material.

- Consider the Environment: Think about where the part will be used. For outdoor applications, materials with UV resistance, like Acrylic or UV-stabilized ABS, are preferable.

- Balance Cost and Performance: While it’s tempting to go for the cheapest option, consider the longevity and performance of the material. Sometimes, spending more on a suitable material can save costs in the long run due to fewer failures and replacements.

- Seek Expert Advice: When in doubt, consult with a material supplier or an experienced injection molder. They can provide valuable insights based on similar projects and applications.

- Utilize Material Selection Tools: Some online tools and resources can help simplify the material selection process by providing information on various plastics and their properties.

Detailed Material Analysis:

Profiling Common Injection Molding Resins

This section provides in-depth profiles of common injection molding resins, focusing on their descriptions, properties, and typical applications. Additionally, comparative tables will be included to rate these materials on relevant attributes, aiding in a clear understanding of each material’s strengths and weaknesses.

1. Polyethylene (PE)

Polyethylene is one of the most commonly used plastics globally, renowned for its versatility and cost-effectiveness. It’s available in various densities, with high-density polyethylene (HDPE) and low-density polyethylene (LDPE) being the most prevalent for injection molding.

Properties:

- High chemical resistance

- Excellent impact resistance (especially HDPE)

- Good moisture barrier properties

Applications:

- Containers

- Household goods

- Automotive parts

2. Polypropylene (PP)

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and elasticity. It’s often chosen for applications that require a good balance between strength, flexibility, and heat resistance.

Properties:

- High fatigue resistance

- Resistant to many chemical solvents, bases, and acids

- Good heat resistance

Applications:

- Medical equipment

- Automotive components

- Consumer goods

3. Polystyrene (PS)

Polystyrene is a versatile and economical plastic, widely used for its ease of molding and consistent properties. It comes in two main types: General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS).

Properties:

- Excellent dimensional stability (GPPS)

- Good impact resistance (HIPS only)

- High clarity (GPPS)

Applications:

- Disposable cutlery

- CD cases

- Appliance housings

- Medical Disposables

4. Acrylonitrile Butadiene Styrene (ABS)

ABS is a popular thermoplastic known for its toughness and rigidity. It’s a terpolymer made from three monomers—acrylonitrile, butadiene, and styrene—each contributing main properties to the final product.

Properties:

- High impact resistance

- Good heat resistance

- Easy to machine and finish

Applications:

- Automotive interior parts

- Electronic housings

- Toys

5. Polycarbonate (PC)

Polycarbonate is a strong, transparent plastic with exceptional impact resistance and temperature tolerance. It’s often used in applications where safety and clarity are essential.

Properties:

- Extremely high-impact resistance

- High temperature resistance

- Optical clarity

Applications:

- Bulletproof glass

- Eyewear lenses

- Electronic components

- Medical Devices

6. Polyamide (Nylon)

Nylon, a type of polyamide, is known for its high strength, temperature resistance, and durability. It’s commonly used in applications that require high wear resistance.

Properties:

- High mechanical strength

- Good thermal and chemical resistance

- Low friction coefficient

Applications:

- Gears

- Bearings

- Automotive under-hood components

7. Thermoplastic Polyurethane (TPU)

TPU is a versatile elastomer that bridges the gap between rubbers and plastics. It offers a unique combination of flexibility, durability, and resistance to oils and greases.

Properties:

- Excellent abrasion resistance

- Good flexibility over a wide temperature range

- High resistance to oils and greases

Applications:

- Phone cases

- Automotive instrument panels

- Medical devices

Comparative Analysis Table

The following table provides a comparative analysis of the above materials based on the main attributes such as impact resistance, heat resistance, and chemical resistance.

Material

Impact Resistance

Heat Resistance

Chemical

Resistance

Flexibility

Cost-Effectiveness

PE

High (HDPE)

Moderate

High

Low

High

PP

Moderate

High

High

High

High

PS

Low (GPPS)

Moderate

Moderate

Low

High

ABS

High

High

Moderate

Moderate

Moderate

PC

Very High

Very High

High

Low

Low

Nylon

High

High

High

Moderate

Moderate

TPU

High

Moderate

High

Very High

Moderate

COC

Moderate

High

High

Low

Moderate

COP

Moderate

High

High

Moderate

Moderate

TPE

High

Moderate

Moderate

Very High

High

Each resin has unique properties that make it suitable for specific applications. The comparative table is a quick reference to evaluate and contrast these materials based on your project’s requirements. Remember, the optimal choice depends not only on the material’s inherent properties but also on how those properties align with the demands of your specific application.

Considering Operating Conditions: How They Affect Material Performance in Injection Molding.

This section reviews the impact of factors like temperature, strain rate, chemical exposure, and environmental conditions such as UV exposure and fatigue loading and provides a case study on selecting materials based on operating temperatures.

Effects of Temperature, Strain Rate, and Chemicals

Temperature

Most plastics have a specific temperature range within which they maintain optimal mechanical properties. Exceeding this range can lead to softening, deformation, or loss of strength, while temperatures below the recommended range may cause brittleness. For example, materials like Polypropylene (PP) maintain good flexibility and toughness at higher temperatures compared to Polystyrene (PS), which becomes brittle. However, after sustained exposure to higher temperatures, PP does not maintain its shape and can warp.

Strain Rate

The Strain rate is the rate at which a load is applied to a material. Some materials, like ABS, show more flexibility and toughness at higher strain rates, making them ideal for products likely to experience sudden impacts. Conversely, low strain rates can lead to creep, where the material slowly deforms under constant stress.

Chemical Exposure

The material’s resistance to chemicals must be considered in environments where exposure to solvents, acids, or bases is likely. Materials like PE and PP offer excellent chemical resistance, while others like Polycarbonate (PC) are more susceptible to damage.

Environmental Factors

UV Exposure: Ultraviolet (UV) radiation can degrade many plastics, causing discoloration, loss of strength, and brittleness. Materials like Polyamide (Nylon) and ABS can be more susceptible to UV degradation unless they are specially treated or stabilized.

Fatigue Loading

Repeated loading and unloading cycles can lead to fatigue in materials. This is a critical consideration for parts that will undergo continuous or cyclic stresses. Materials like TPU and Nylon are known for their excellent fatigue resistance.

Factors to Consider During Prototype Material Selection

Mechanical

We strive to replicate production part quality, without sacrificing speed.

Tolerances

Does the part require any unusually tight tolerances?

Environmental

Is the part used in environments that require consideration such as chemical resistance, high/low temperature exposure, humidity, etc.

Assembly

Prototype parts to be assembled need to be molded from compatible materials in some assembly methods such as ultrasonic welding, laser welding, adhesive bonding, etc

Sterilization

Will the product be a single use sterilized disposable sterilized or a sterilized reusable? What will be the sterilization method?

Regulatory

ISO, FDA, UL, IEC, USP are examples of regulatory agencies that have specific requirements for biocompatibility, food contact, flammability, etc.

Electrical

Certain applications require plastics to function as anti-static, static dissipative, ESD protective, conductive or insulating.

Cost

The part needs to be within cost targets while meeting all other requirements.

Aesthetic

Transparency, color, gloss, surface finish, etc.

Special requirements

Transparency, color, gloss, surface finish, etc.

Case Study:

Selecting Material Based on Operating Temperatures

Background: A client approached us with a requirement for a high-performance component to be used in an automotive engine. The part needed to withstand high temperatures, ranging from -30 °C in cold environments to 150°C near the engine.

Approach: We conducted a series of tests to identify a material that could maintain its mechanical properties across this wide temperature range. The tests focused on assessing tensile strength, impact resistance, and thermal stability at various temperatures.

Materials Tested:

- ABS: Known for its high impact resistance but with a tendency to soften at higher temperatures.

- Nylon: Offers excellent heat resistance and strength but can absorb moisture, affecting its properties.

- PEEK (Polyether Ether Ketone): A high-performance thermoplastic known for maintaining strength and stiffness at high temperatures.

Testing and Results:

At low temperatures, all materials maintained good performance, but at higher temperatures, ABS showed signs of softening and deformation.

Nylon performed well at mid-range temperatures but experienced a slight loss of strength at the higher end of the spectrum.

PEEK displayed outstanding performance across the entire temperature range, maintaining its mechanical properties even at the highest temperatures.

Solution

Based on the testing, PEEK was selected as the material for the component. Its ability to withstand extreme temperatures without significant degradation of its properties made it the ideal choice for this application.

The case study illustrates the importance of thorough testing and evaluation to ensure that the chosen material not only meets the technical requirements of the project but also performs reliably in the actual operating environment for factors such as temperature, strain rate, chemical exposure, UV radiation, and fatigue loading.

Special Focus on High-Performance Materials:

PEEK and ULTEM

In injection molding, high-performance materials like PEEK (Polyether Ether Ketone) and ULTEM (Polyetherimide) represent the great benefit of material engineering, offering exceptional properties for demanding applications. This section analyzes these materials, focusing on their properties, suitable applications, and the crucial aspect of cost versus performance tradeoffs.

PEEK: Properties and Applications

PEEK is a semicrystalline thermoplastic with outstanding mechanical and chemical resistance properties, even at very high temperatures. It is known for its robustness and ability to perform in severe service conditions. It is also VERY expensive.

Properties:

- High-Temperature Resistance: PEEK can withstand continuous use at temperatures up to 250°C (482°F), making it ideal for high-heat environments.

- Mechanical Strength: Offers excellent strength and stiffness, maintaining its properties even under sustained load and high temperatures.

- Chemical Resistance: Exceptional resistance to a wide range of chemicals, including hydrocarbons and organic solvents.

- Biocompatibility: Suitable for medical implant applications due to its biocompatible nature.

Applications:

- Aerospace components such as engine parts.

- Medical implants and surgical instruments.

- Semiconductor machinery parts.

- Oil and gas industry components for extreme environments.

ULTEM: Properties and Applications

ULTEM is an amorphous thermoplastic known for its high thermal properties, flame resistance, and strength. It offers excellent dimensional stability and electrical insulation properties.

Properties:

- High Heat Resistance: Maintains stability and integrity at elevated temperatures, withstanding continuous operation at temperatures up to 180°C (356°F).

- Flame Resistance: Inherently flame retardant with low smoke emission, making it suitable for electrical and electronic applications.

- Strength and Rigidity: Provides high strength and stiffness, along with excellent dimensional stability.

- Transparency and Colorability: Offers the unique combination of being able to be both transparent and easily colored, a rare feature among high-performance plastics.

Applications:

- Electrical and electronic components, such as connectors and insulators.

- Aircraft interiors and components require high strength-to-weight ratios.

- Medical devices and pharmaceutical applications.

- Automotive parts require high heat resistance.

Cost vs. Performance Tradeoff Considerations

While offering superior properties, PEEK and ULTEM come at a significantly higher cost than standard injection molding plastics like ABS or Polyethylene. The decision to use these materials should be driven by the specific requirements of the application and the value added by their advanced properties.

For example, the higher cost of ULTEM is justified in aerospace applications where high temperature and flame resistance are non-negotiable for safety. Similarly, PEEK’s biocompatibility and strength in the medical field make it an ideal choice for implantables despite its higher cost.

PEEK and ULTEM are high-end materials used in injection molding, offering properties unattainable with standard materials. Their use should be considered when the application demands extraordinary performance that can justify the additional expense. Understanding the specific requirements of your project and how these materials can meet those needs is critical to making an informed decision about whether their higher cost is a worthwhile investment.

Contact Protoshop Inc. Today for Injection Molding Material Selection Assistance

The selection of materials for injection molding is a nuanced process that demands careful consideration of various factors.

- Material Properties: Understanding the mechanical, thermal, and chemical properties of different materials is fundamental to selecting the right one for your application.

- Application Requirements: Align material properties with the specific requirements of the product, including its operational environment and functional demands.

- Cost-Effectiveness: Balance performance with cost-effectiveness, considering not only the material cost but also the implications for the manufacturing process and product lifespan.

- Experimentation and Testing: Emphasize the importance of experimentation and validating material choices through testing. Prototyping and real-world trials are crucial for ensuring that the material performs as expected under operational conditions.

- Continuous Learning: Stay informed about new materials and technological advancements. The field of injection molding is dynamic, with ongoing innovations in materials and processes.

Ultimately, the successful selection of injection molding materials hinges on a blend of theoretical knowledge, practical experience, and ongoing experimentation. By leveraging the resources available and continually testing and validating your choices, you can ensure the development of high-quality, durable, and cost-effective injection molded products. Protoshop can help recommend suitable materials for your application and aid in the experimentation phase by producing quick-turn prototype molds and molding production-equivalent components in multiple materials for testing.