-

How Tariffs Are Changing the Plastic Injection Molding Industry

Global instability and newly imposed international tariffs have the potential to disrupt the global manufacturing industry. Among the hardest hit industries is plastic injection molding, a critical component in the prototyping and production of plastic parts across industries like automotive, consumer electronics, medical devices, and industrial equipment.With tariffs on imported ...

READ MORE -

How Injection Molding Helps the Automotive Industry with High-Performance Lightweight Parts

In the automotive industry, injection molded parts can improve vehicle performance, fuel efficiency, and sustainability by balancing the need for strength, weight reduction, and cost-effectiveness. Protoshop provides rapid prototype injection molding and tooling solutions to help the automakers stay ahead of the curve. Why Lightweight Parts Matter in the Automotive ...

READ MORE -

Exploring Various Techniques for Post-Molding Operations

Plastic injection molding is highly effective at producing near-net-shape parts, but additional steps are often needed to achieve a part’s final requirements. Post-molding operations refer to any processes performed on a molded part after it’s ejected from the mold, in order to impart the final shape, features, or finish. These ...

READ MORE -

What’s Next in Injection Molding: Predictions for 2025

The injection molding industry has long been known for its precision and efficiency in manufacturing parts across different sectors. As we continue through 2025, exciting changes are underway that could significantly alter how we approach production. Driven by new technologies, shifting consumer preferences, and a growing focus on sustainability, the ...

READ MORE -

Why First-Time Inventors Should Use Professional Prototyping

For first-time inventors, turning an idea into a real product can be both exciting and overwhelming. With a concept that has the potential to be a game changer, the challenge lies in bringing that idea to life. After conducting market research and confirming viability, the next steps involve refining the ...

READ MORE -

The Different Types of Prototyping Techniques and When to Use Them

Prototyping is a necessary element of the innovation and product development process. Creating prototypes allows designers, engineers, and business stakeholders to touch, interact with, and test product concepts without investing fully in manufacturing. This helps refine designs, validate functionality, and reduce risk before committing to full production. There are a ...

READ MORE -

An In-Depth Look at Low-Pressure Injection Molding

Injection molding is the most efficient method for producing large quantities of plastic parts at high speed and low cost. However, this process is not always compatible for manufacturing parts that encapsulate sensitive electronic components; high melting temperatures and pressures required for standard injection molding can damage these sensitive components. ...

READ MORE -

A Simple Guide to Cycle Time in Plastic Injection Molding

Cycle time is a key metric in plastic injection molding that affects efficiency, cost, and quality. For companies that fabricate rapid molds for injection molding prototypes, like Protoshop Inc., optimizing cycle time and part cost may not be the primary goal but should be considered early in the design phase ...

READ MORE -

How to Evaluate and Test the Functionality of a Plastic Prototype

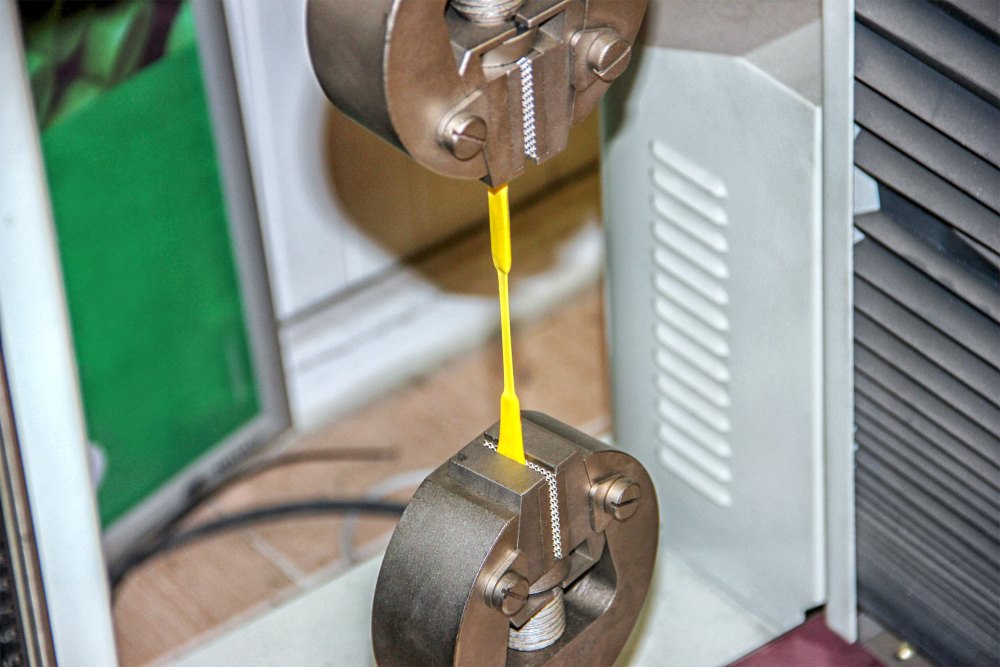

Rapid prototype plastic injection molding is a powerful tool for product development, offering a fast and affordable way to create new plastic products. However, the work doesn’t end once the prototype is made. Testing is necessary to ensure that the prototype performs as expected. Without proper testing, even the most ...

READ MORE -

The Future Trends of the Injection Molding Industry

Injection molding is a widespread manufacturing process that produces parts by injecting molten material into a mold cavity. The material solidifies within the mold, which is then opened to eject the molded part. This high-volume process is utilized across industries like automotive, medical, consumer goods, and more due to its ...

READ MORE