-

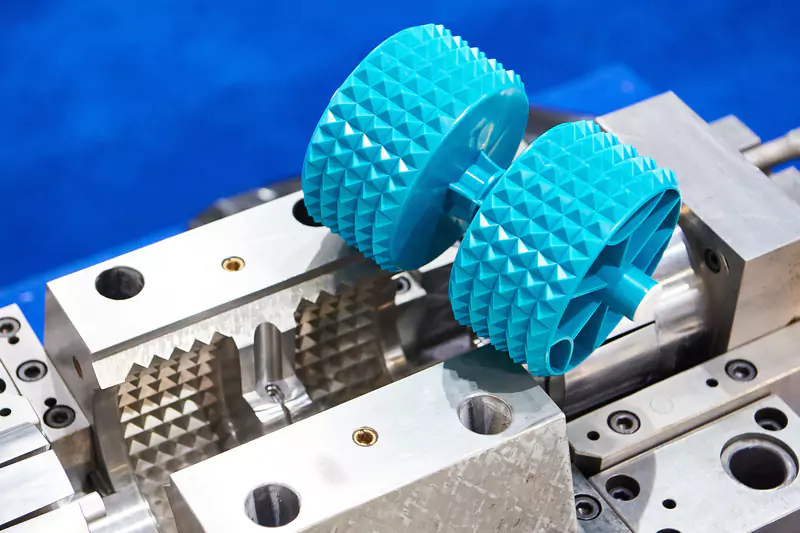

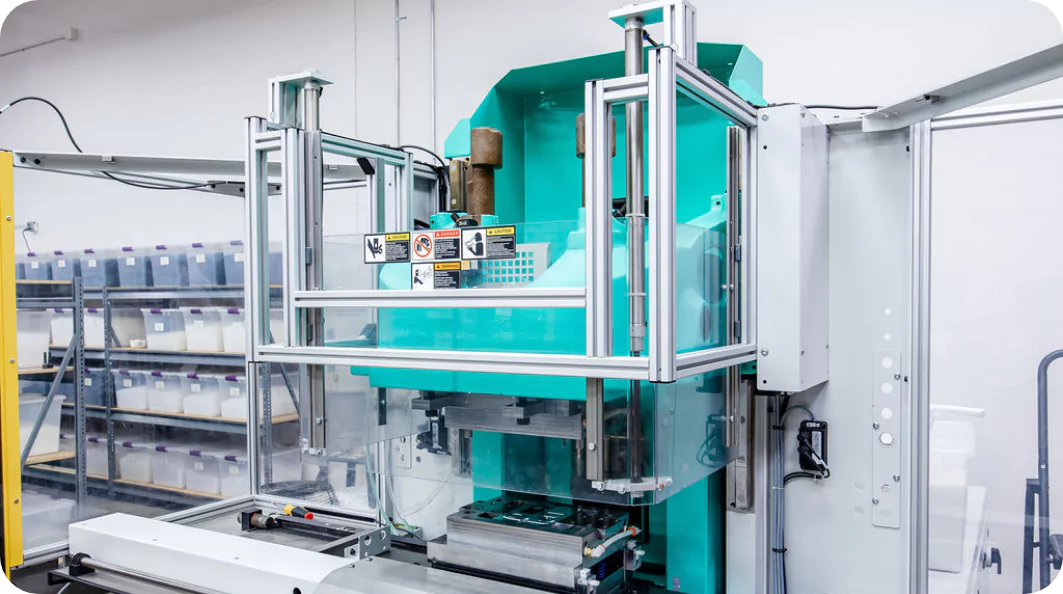

Cost-Effective Injection Mold Fabrication: Balancing Quality & Budget

The quality of an injection molding tool directly impacts product quality and overall production costs. Balancing the need for high-quality molds with budget constraints is a challenge product developers and manufacturers contend with continually. Strategies for achieving cost-effective mold fabrication without compromising quality will maximize the value of an injection ...

READ MORE -

Rapid Prototyping Techniques: Definition, Methods, and Advantages

Rapid prototyping has become an invaluable tool for companies looking to accelerate development and quickly bring new products to market. In technology, manufacturing, and consumer goods, getting products to customers ahead of the competition is critical. This area is where leveraging rapid prototyping during the design phase can provide significant ...

READ MORE -

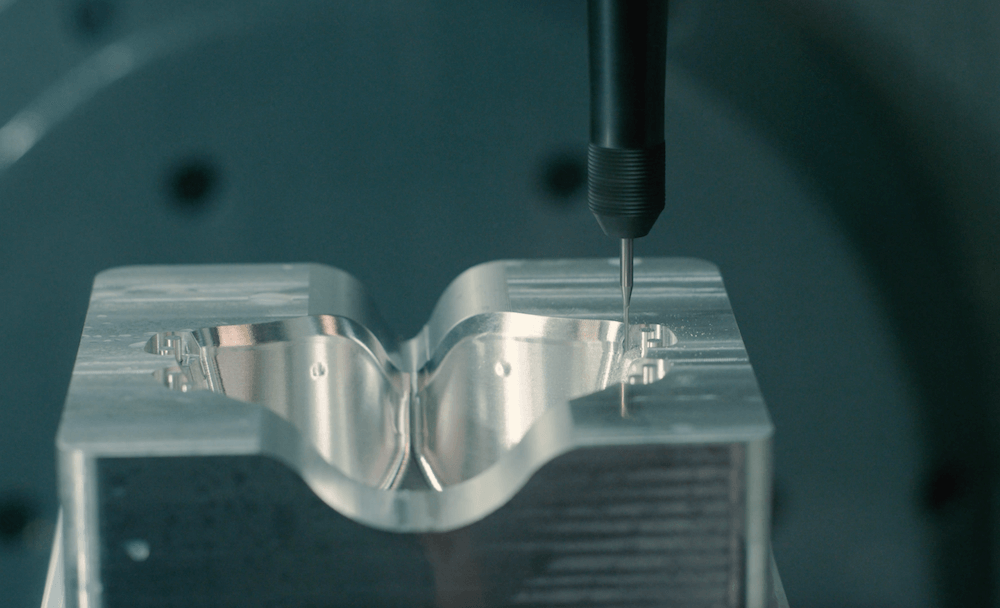

How Should I Prototype? Machined Parts, Print 3D Parts, or Fabricate a Prototype Mold

How should I prototype? Machined parts, print 3D parts, or fabricate a prototype mold Introduction Once a design engineer completes the first draft of their product design, the next step is to create a plan for how it will be fabricated, tested, and developed. There are three basic methods of prototype fabrication: 1) CNC machining, 2)

READ MORE