Prototyping is an essential step in the product development process that allows designers to test concepts, evaluate form and function, and refine designs. Choosing the appropriate prototyping technique is very important for creating effective prototypes that provide meaningful insights without requiring excessive time and costs.

The prototyping method must align with key requirements like intended purpose, geometric complexity, material properties, and quantity needed. Factors like budget, available capabilities, and needs for future modifications should also guide the selection process. Trade-offs exist between rapid low-fidelity and slower high-fidelity methods that must be balanced for each project.

Understanding Prototype Tooling

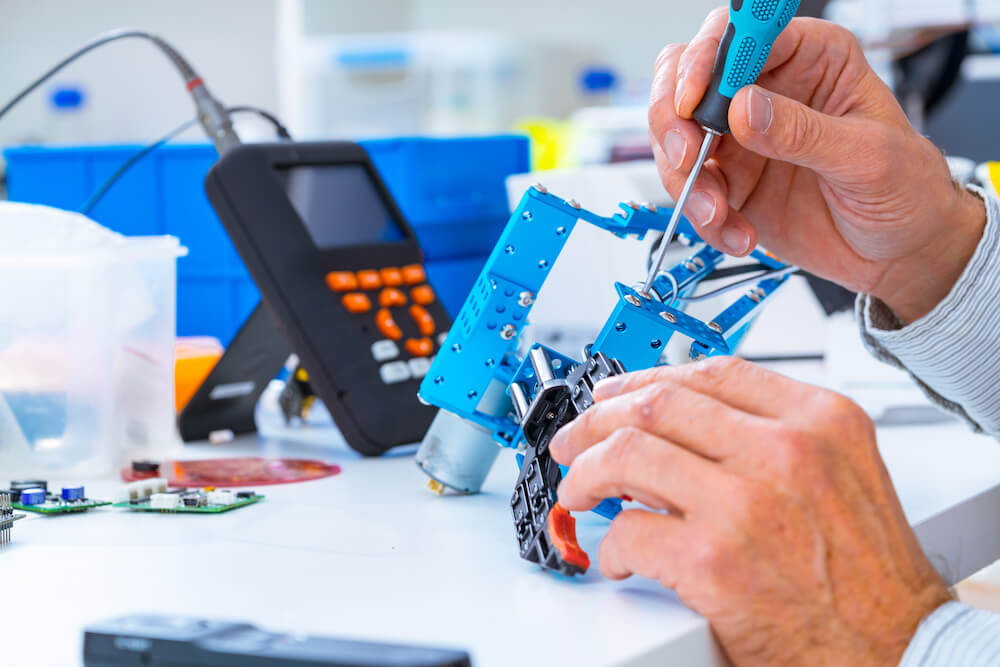

Prototype tooling refers to the methods and equipment used to create prototype parts and products for testing and evaluation. This includes tools like molds, patterns, jigs, fixtures, and various forms of tooling that enable the prototyping of concepts without full-scale production tooling.

Prototype tooling allows designers to physically realize designs and gather insights early in the product development process. Testing functional prototypes can reveal design flaws, demonstrate proof-of-concepts, and provide valuable feedback to improve the design before committing to production. This reduces risk and saves time and costs compared to finding issues after production tooling is made.

Prototype tooling is commonly used in the automotive, industrial equipment, consumer products, electronics, and medical devices industries. Specific applications include creating concept models, functional prototypes, pre-production samples, and low-volume production bridging tools. Common scenarios are evaluating ergonomics and aesthetics with form models, performance testing with functional prototypes, and validating capabilities with pilot runs.

Overview of Prototype Tooling Methods

A wide variety of prototype tooling methods are available to turn a design into a physical prototype. The major technique categories include:

Rapid Prototyping

Rapid prototyping typically refers to additive manufacturing processes that build parts layer-by-layer without part-specific tooling. Common methods include fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and PolyJet. Benefits include speed, low cost for one-offs, and complex geometries. Limitations are material properties and accuracy.

CNC Machining

Both manual and CNC machining are used for prototyping. CNC allows automation for improved consistency and complexity. Typical processes are milling, turning, and drilling. Ideal for durable, functional prototypes from metals or plastics. Limited on shapes by cutting tool access.

Injection Molding

Low-cost prototype molds with 3D printed inserts can be used for 10-100+ parts. Production-quality prototype molds machined in aluminum or brass provide 500-10000+ parts. These molds are ideal for rapid prototyping injection molding, allowing you to test designs, ergonomics, and assemblies before full production.

Vacuum Casting

Casts prototypes by pouring material into silicone molds under vacuum. Quick and relatively low cost. Limited material selection and mold life. Common for low-volume parts or bridge tooling before production volumes.

Sheet Metal Prototyping

Cutting, bending, and welding sheet metal allows fabricating enclosures and structures. It is relatively fast and inexpensive, useful for concept models and design testing before committing to die tools.

Other Methods

Additional techniques, such as thermoforming, investment casting, and urethane casting, provide other capabilities. Selection depends on the need for realism, functionality, tooling cost, and lead time.

Key Considerations for Prototype Tooling Method Selection

With various prototyping methods available, narrowing down the options to find the best fit for a project’s specific needs can be challenging. Carefully weighing each consideration against the key requirements, capabilities, and constraints helps determine the ideal prototyping technique for the application.

The following chart categorizes key considerations such as complexity, cost, speed, strength, and functionality across various prototyping methods to assist in making an informed decision. This breakdown provides a clear comparison to help select the most suitable technique for your specific project needs:

| Complex Design | Cost | Speed | Strength | Functionality | |

| Rapid Prototyping | High | Low | High | Low | Low |

| Machining | Medium | Medium | Medium | High | High |

| Injection Molding | High | Medium | Medium | High | High |

| Casting | High | Low | Medium | Medium | Medium |

| Sheet Metal Bending | Low | Low | Medium | Medium | Medium |

| Thermoforming | Low | Medium | Medium | Medium | Low |

| Investment Casting | High | High | Medium | High | High |

Purpose of Prototype

The intended use of the prototype guides selection. Methods like 3D printing or CNC may work for concept models, while functional testing requires more robust techniques. Define how the prototypes will be evaluated. Products in the medical device space, for example, must undergo rigorous functional testing that requires the parts to be produced in the manner that they will ultimately be fabricated.

Material Properties

Consider strength, aesthetics, and other material property needs. Rapid prototyping has limited material choice compared to machining, molding, or casting. Select the process capable of utilizing the appropriate material.

Geometric Complexity

Simple shapes allow more options, while complex geometries limit choices. Assess design elements like undercuts, deep channels, and fine features and the level of effort required to form these features in the selected prototype tooling method.

Quantity and Iteration Frequency

Volume and expected changes guide tooling decisions. Low-volume single parts suit rapid prototyping, while higher volumes justify soft tooling. Frequent iterations make modular tooling components favorable.

In-house vs. Outsourcing

In-house systems reduce cost and lead time for iterations but require capital investment. Outsourcing increases capacity and expertise without a burden on equipment.

Budget and Timeline

Weigh the relative costs and development times for each method. Lower tooling cost techniques often have longer lead times. Based on project needs, prioritize the budget or schedule.

Selecting the Appropriate Prototype Tooling Method

To choose the optimal prototyping technique, it is imperative to carefully evaluate requirements, capabilities, trade-offs, and future needs:

Aligning with Prototyping Requirements

The prototyping method must match the project requirements, such as functionality, accuracy, material choice, complexity, quantity, and lead time. List all requirements and capabilities to find the best process fit. Selecting an inappropriate method can lead to prototypes that fail to provide the necessary validation, resulting in development delays and additional costs.

Balancing Trade-offs

Prototyping decisions often involve trade-offs between speed, cost, quality, and material options. Generally, the faster and cheaper a process is, the more limited its capabilities. For example, 3D printing is fast with low upfront cost but has drawbacks for finished appearance, strength, and material choice. Balance trade-offs based on the current priority: fast concept validation, realistic testing, or mimicking production.

Considering Future Iterations and Modifications

The selected method should be flexible enough to accommodate changes in future prototype iterations. Consider how easy it is to modify and rework the tooling for an evolving design. Production-focused tooling like metal molds can be restrictive for iterations, while modular tooling components can speed adaptation. Planning ahead allows for efficient progress through the refinement process.

Investing in Prototypes

Selecting the right prototyping method is vital to efficient and effective product development. Aligning the tooling approach with current-stage priorities while considering future needs allows companies to maximize learning while minimizing wasted effort.

Whether the focus is proof-of-concept, design validation, or pre-production, choosing the prototyping technique that balances the application’s capability, flexibility, and cost will yield high-value prototypes. Prototyping itself is an iterative process, so being able to quickly adapt methods positions teams to glean insights faster and accelerate development.

The team at Protoshop would be more than happy to help you find the right prototype tooling method for your project. Reach out to our team today to learn more.