Tooling strategy plays a critical role in product development and manufacturing processes. Choosing the right tooling approach is essential as products progress from initial concept to finished production. While production tooling is designed for mass manufacturing, prototype tooling offers a cost-efficient alternative for product development and early-stage development, so it often makes sense to include it in the project budget. Let’s explore the key differences between prototype and production tooling and the advantages of utilizing prototype tooling strategies to improve product development timelines.

Understanding Prototype Tooling in Manufacturing

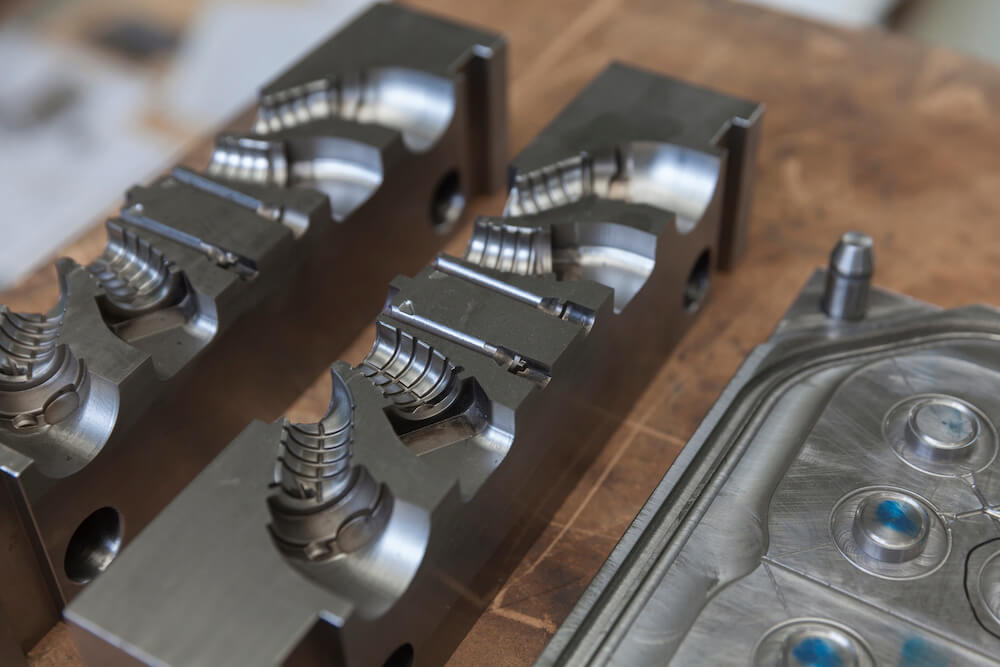

Plastic injection molding tooling refers to molds used in manufacturing operations to produce consistent and high-quality plastic parts. Production tooling is used to create a large number of low-cost parts for the market. These tools are expensive and take months to produce. Prototype plastic injection molding tooling is designed more simply and is less expensive to fabricate; therefore, it can be used in product design and development stages to create plastic prototypes quickly. These plastic prototype parts allow designers to receive production-equivalent parts in hand to test and refine concepts before major investments in full-scale production tooling.

Choosing The Right Tooling Approach

Production tooling is optimized for high-volume manufacturing once the design is finalized. If the parts and assemblies are untested, then design flaws can be found after the production parts are molded. At that point, the cost to change the production tool and the cost to product launch timelines are the highest. Prototype tooling enables rapid iterations during the design process before committing to more expensive production tooling. Although creating prototype tooling adds expense to the budget, most times, incorporating “real” plastic prototypes into the development schedule accelerates time-to-market and avoids unnecessary costs.

Differences Between Production and Prototype Tooling

Production injection molding tooling consists of specialized tools engineered for high-volume, consistent output. Production tooling is fabricated from hardened steel, typically has multiple cavities, and incorporates automated side-pull mechanisms to create part geometry.

In contrast, prototype tooling utilizes less expensive materials, softer metals that are easier to cut, and less automated methods to create prototypes and low-volume test runs. The focus is design refinement rather than maximum output.

Advantages of Prototype Tooling

Prototype tooling provides significant advantages over investing in full production tooling in the early stages of product development:

Faster Development Cycles and Reduced Lead Times

Prototype tooling is designed to be manufactured quickly. Lead times can be cut from multiple months to produce production tools to days or one week for prototype molds and processes. This enables the product developer to get parts in hand to test and evaluate earlier in the design cycle.

Accelerated Design Iterations

The quick lead times of prototype tooling allow engineers to test several concept variants in a short timeframe or iteratively develop a single design as testing instructs the design direction. This facilitates getting feedback and improving early in development before finalizing the design. No analysis paralysis occurs; just make a mold and test it.

Cost Savings from Flexibility

Prototype injection molding tooling is made from softer metals like aluminum and brass instead of steel. Softer metal is easier (i.e., faster) to cut, and therefore the mold is less expensive. Side-action core pins are manually loaded into the mold and manually removed from the part post-molding. This provides major cost savings and flexibility compared to hardened steel production tools with automated side- or rotary-action mechanisms.

Easy and Affordable Design Adjustments

Changes are practically guaranteed during product development. Otherwise, it would be called product design, not development. Design tweaks with production tooling can require expensive and time-consuming reworks, not only because the cavities are constructed in hardened steel but also because there are multiple cavities to modify. If the design change is not a metal-safe change to the mold, steel slugs must be welded into each cavity, and the geometry re-cut multiple times. Single-cavity prototype tooling can be modified quickly and cost-effectively in soft metals, even for non-metal-safe changes. A pocket is cut into the mold, an aluminum or brass piece is pressed in, and the geometry is recut.

Reduced Risk with Design Validation

Prototype tooling allows manufacturers to evaluate and refine the design through real-world testing of production equivalent parts before investing in production tools. This reduces risk by identifying flaws early when design and tool changes are cheaper. Prototype plastic injection molded parts can be incorporated into user and clinical trials to validate the design. For products like in vitro diagnostic (IVD) devices, production equivalent parts must be used for testing before launch to ensure the assay works as intended and to satisfy regulatory requirements.

Cost-Efficient Strategies with Prototype Tooling

A major advantage of utilizing prototype tooling is cost-efficiency throughout the product development process. Even though the addition of prototype tooling seems like an increase in project costs, the benefits often reduce capital expenditure overall and reduce risk to project timelines:

Early Design Refinements

Benchmark testing helps identify design flaws and opportunities for improvement early in the product development cycle, while changes are quick and inexpensive to implement. Prototype tooling can be modified incrementally to build parts to test and refine whole products or isolated design details. For example, critical features like snaps or elastomeric seals cannot be replicated well by other rapid prototyping means but can be quickly molded with prototype injection molding tools.

Avoiding Costly Reworks

Having design flaws emerge before investing in production tooling prevents very expensive reworks down the line. Without prototype injection molded parts to flush out these design features, the risk increases that the production molds will require iterative refinement; the design flaws are discovered too late. Finding these issues with parts created from prototype injection molding results in major cost savings.

Reduced Risk of Design Lock-In

Prototype plastic injection molding tools are best used as the design evolves and part features and materials are evaluated. After production tooling has been paid for and made, design and part material changes can be too costly to implement, and/or product launch delays cannot be permitted. This often results in launching a product with known deficiencies or flaws.

Elevate Your Prototyping Journey with Protoshop Inc.

Choosing the right tooling approach can make all the difference in developing products efficiently. Prototype tooling enables cost-effective refinement before major investments in production tooling. Partnering with Protoshop Inc. provides access to expert guidance and leading-edge prototyping technologies. Contact us today to explore how prototype tooling can accelerate your next product launch. Our innovative solutions will elevate your prototyping journey.