Prototyping is a critical step in product development, allowing product developers and engineers to create physical manifestations of product concepts and test them before committing to full-scale, expensive production molds. However, prototyping can be a major investment, requiring custom mold fabrication, material selection, process setting, and quality testing. For manufactured plastic and rubber parts, injection molding has become the most common method of producing prototypes due to its ability for rapid fabrication coupled with precision results.

With the right approach to prototyping, product developers can gather critical product feedback, optimize designs, and minimize tooling rework down the line. This reduces overall development risk and time-to-market. By following best practices, companies can save significant costs and headaches when preparing their products for full-scale manufacturing with custom molds and other production tooling.

Understanding Injection Molding for Prototype Mold Fabrication

Injection molding is a common manufacturing process for producing plastic parts in high volume. It works by heating plastic resin to a molten state, after which the liquid plastic is injected under high pressure into a mold cavity. Inside the mold, the plastic cools and solidifies into the final part shape.

While designed for mass production, injection molding is also ideal for creating prototype parts during product development. This is due to several key advantages:

- Speed and Efficiency: Injection molds can be fabricated within weeks and can rapidly produce dozens or hundreds of sample parts. This allows for prototypes to be quickly iterated.

- Accuracy: The molds are CNC machined to precise tolerances, which are necessary for accurately testing product fit, form, and function.

- Complexity: Intricate part geometries with optimized injection flow paths can be created in injection molds, allowing replication of nearly all product features.

- Repeatability: Consistent plastic melt conditions and part cooling inside the mold enable each prototype iteration to achieve high repeatability.

- Surface Finish: Prototype parts can achieve excellent surface finishes to enable the evaluation of aesthetic qualities.

- Low and High Volume Capability: The molding process enables flexibility to produce anything from a few prototype parts up to thousands in short order.

By offering rapid fabrication of high-quality and repeatable prototypes, injection molding has cemented itself as the foremost solution for enabling physical product testing and design improvements during development. Now, let’s dive into the process of mold fabrication.

Planning and Design

The process of prototype mold-making begins even before any material gets machined or molded. Crucial upfront planning and design considerations can dictate project success down the line.

Step 1: Conceptualizing the Prototype

Clearly defining prototype objectives is vital. This helps orient the design priorities. For example, focusing on accuracy for an electronic enclosure versus aesthetics testing for a consumer product.

Close collaboration between designers and manufacturing engineers also reduces errors. Designers can conceive aspirational concepts, while engineers suggest any improvements for moldability and function. This tag-team approach aligns design intent with manufacturing best practices.

Step 2: Choosing the Right Materials

Material selection requires evaluating factors like heat tolerance, strength, cosmetics, and safety. But also consider machine compatibility, as some plastics melt or flow better. Common prototype mold materials include:

- Polypropylene (PP): durable, flexible, chemically resistant

- Acrylonitrile Butadiene Styrene (ABS): heat/chemically resistant

- Polycarbonate (PC): Extremely high-impact and temperature resistance, optical clarity

Keep cost in mind, too, when choosing materials. More exotic plastics can have exponentially higher prices. Prioritize must-have mechanical or aesthetic properties first before diminishing returns set in on marginal upgrades. Getting the planning and design right means already overcoming some of the biggest hurdles, even before mold fabrication begins.

Mold Design and Development

With objectives and materials selected, mold design takes center stage. This is where part geometry gets translated into mold components capable of forming the prototypes.

Step 3: Creating a Mold Design

Mold design is a complex 3D modeling task with critical dimensions and clearances to incorporate. Specialized CAD packages like Moldflow handle these sophisticated programs. Key design considerations include:

- Parting surfaces: where halves separate

- Lifters and ejector pins: to remove parts

- Cooling channels: for rapid heat extraction

- Runners and gates: liquid plastic flow paths

Getting the mold design right from both manufacturing and molding perspectives leads to fewer machining errors and smoother startups down the line.

Step 4: Simulating the Mold Process

Once a mold design is complete, simulations help predict potential issues before any metal gets cut. By virtually modeling factors like melt flow, cooling rate, shrinkage, and warp, trouble areas can be spotted early.

Tweaking the digital mold design is much quicker than attempting physical fixes later in machined metal molds. Simulation iterations also save costs over mold reworks. The insights gained help stage the most efficient fabrication process by resolving problems before they ever manifest physically.

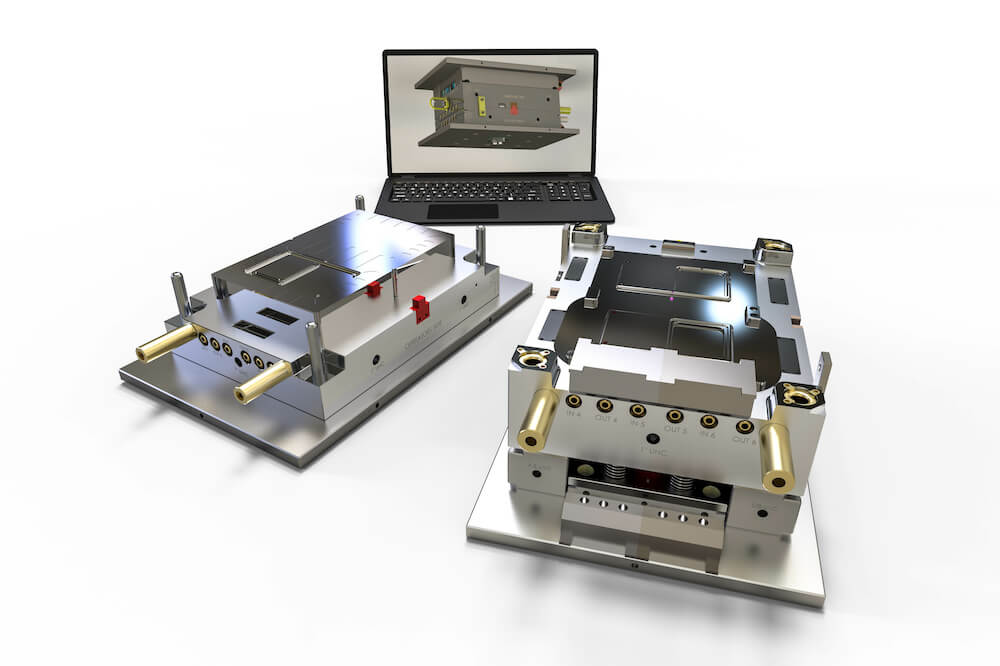

Prototype Mold Fabrication Process

With a fully vetted mold design, machining and assembling the custom mold takes place across carefully orchestrated steps.

Step 5: Machining the Mold

Mold components get precisely cut from metal blocks, usually stainless steel or aluminum. CNC machines translate CAD dimensions into cutting paths to carve cores, cavities, ejector pins, and cooling channels. Quality checks along the way measure accuracy against specifications. Any deviations outside tight tolerances would compromise mold performance and part quality.

Step 6: Assembling the Mold

All components get cleaned and prepped prior to mold assembly. Careful alignment ensures parting line surfaces meet evenly without gaps and ejector pins/channels connect properly. Testing puts assemblies through opening/closing cycles at prototyping heat/pressure levels. Only a fully functioning assembly will get approved, as issues found later prove difficult to fix once in production.

A meticulous fabrication process sets the stage for smooth injection trials later. Rushing can introduce subtle problems that then manifest as defects in early samples. Investing in robust QA avoids these downstream issues.

Injection Molding the Prototype

With a fully prepped mold, the exciting task of producing actual prototype parts takes place. But the first iterations reveal plenty of learning.

Step 7: Injection Molding Process

With a prototype mold fully assembled and validated, the next crucial phase is integrating it within injection molding machines to produce the first plastic parts. These complex systems precisely heat polymer resin, inject it into cavities at high pressures, cool and cure the plastic, and eject finished parts in a cyclic fashion.

Getting the process parameters right requires an iterative approach while closely monitoring part quality shot-to-shot for incremental improvements. Key factors influencing outcomes include:

- Barrel & Mold Temperatures: Improper thermal profiles during plasticization or mold cooling stages readily create flow irregularities and curing defects. Finding optimal settings mitigates such issues.

- Injection Fill Pressure: Inadequate pressure leads to short-shot parts with incomplete mold cavity fills. Excess pressure risks flash around parting lines or damage to thin walls and side actions.

- Pack & Hold Pressure: Cranking up pack pressure substantially increases part weight and density. Meanwhile, low pressure causes visible sink marks and voids.

- Cycle Timing: Prematurely opening the mold prior to proper solidification results in permanent shape distortions. Overly long cycles reduce throughput.

With so many interdependent variables at play, injection molding requires practice to master, especially for prototype molds. Minor tweaks make major differences. Patience during initial sampling builds process intuition for each material and mold combination to achieve repeatable, high-quality parts.

Step 8: Quality Checks and Troubleshooting

Early inspection against design specifications validates whether objectives were met. Short shots, sink marks, and warpages are common molding defects requiring adjustment. Potential fixes include:

- Increasing injection pressure for denser fills

- Tweaking process temperatures for improved flow

- Slowing cycle times for better curing

- Spot polishing any roughened mold surfaces

While daunting at first, defects provide learning opportunities to improve the mold and process. Parameter refinement and minor mold alterations better optimize performance over subsequent iterations. Continual testing ultimately achieves prototype objectives. The injection trials effectively break in and validate the fabrication process while uncovering enhancement areas moving forward. Molding trials may even direct plastic part changes to improve manufacturability and repeatability.

Evaluation and Iteration

The initial prototype sampling provides data to assess successes and shortcomings in meeting design goals. This feeds iterative adjustments for incremental improvements.

Step 9: Analyzing the Prototype

A thorough analysis of the initial prototype parts against the original specifications is crucial for evaluating how well targets were met. Both quantitative metrics and qualitative feedback should guide this process.

On the quantitative side, each sample gets judiciously measured and tested for:

- Dimensional Accuracy: Carefully calibrate part dimensions using precision tools like calipers and micrometers, then compare them to CAD models. Any noticeable dimensional deviations can impact the achievement of fit, form, and tolerances.

- Wall Thickness Consistency: Monitoring wall thickness in different locations through cross-sectional examination. Significant thickness variations create weaknesses while also indicating potential mold fill and curing issues.

- Strength Testing: Applying destructive test methods per industry standards to validate mechanical properties. This includes checks for tensile strength, flexural modulus, Izod impact resistance, and hardness values. Shortfalls expose material or processing deficiencies.

On the qualitative side, visual appearance evaluations and stakeholder reviews give invaluable subjective perspectives:

- Visual Inspection: Rich sensory feedback around subtle shape inaccuracies, poor surface finish, part warpage, weld line visibility, and cosmetic defects. Our visual perception quickly notices flaws.

- Stakeholder Testing: Allowing intended end users to physically test parts for ergonomics and real-world usability provides feedback that specifications may overlook. Their usage validation and ideas for improvement are vital.

Analyzing from both the quantifiable metrics and experiential perspectives offers a comprehensive appraisal of how closely the prototypes met expectations. Any underlying issues also surface for decisive corrective action during mold and process refinement.

Step 10: Refining the Mold and Prototype

Analysis may reveal needing tighter process controls, mold adjustments, or even updated material choices if severe issues surface. Typical iterative enhancements involve:

- Smoothing surface defects in the mold

- Altering thermal regulation to fix warpage

- Incorporating vents to eliminate trapped gasses

- Reinforcing thin walls prone to breaking

The goal is to drive progressive part enhancement through controlled, measured changes while avoiding reactionary overcorrections. Data fuels refinement.

Recurring comparison testing after each adjustment provides metrics on iteration effectiveness towards ultimately achieving design validation. This cyclical process cements prototyping efficacy.

Take the Next Step with Protoshop

Dio you have a product vision and need to test concepts with physical prototypes? Or perhaps existing prototypes fall short, and you require solutions to achieve accuracy? Or perhaps you need to de-risk the molding process to better understand issues that arise, before production molds are commissioned? In all cases, the team at Protoshop stands ready to deliver.

With over 25 years of specialized expertise in prototype molding and a customer-focused approach, Protoshop has helped bring countless products to market. Our combination of premium quality prototype parts, flexible iterative options, and personal guidance ensures your project is set up for success. Reach out today for more information.