-

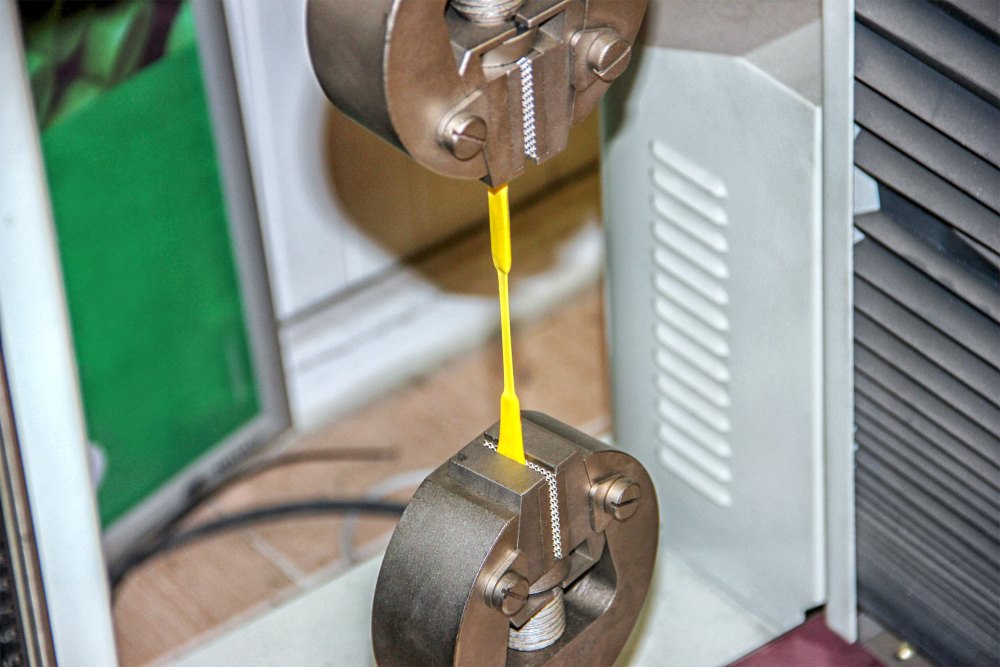

How to Evaluate and Test the Functionality of a Plastic Prototype

Rapid prototype plastic injection molding is a powerful tool for product development, offering a fast and affordable way to create new plastic products. However, the work doesn’t end once the prototype is made. Testing is necessary to ensure that the prototype performs as expected. Without proper testing, even the most ...

READ MORE -

The Future Trends of the Injection Molding Industry

Injection molding is a widespread manufacturing process that produces parts by injecting molten material into a mold cavity. The material solidifies within the mold, which is then opened to eject the molded part. This high-volume process is utilized across industries like automotive, medical, consumer goods, and more due to its ...

READ MORE -

Common Mistakes to Avoid When Designing Plastic Prototypes for Injection Molding

Precision plastic prototyping ensures success when transitioning to full-scale injection molding production. Even small oversights or mistakes in the design phase can lead to significant issues down the line, from part defects and quality problems to production delays and increased costs. By understanding common pitfalls and missteps early in the ...

READ MORE -

Everyday Plastic Products That Are Injection Molded Parts

Plastic injection molding is the backbone of modern manufacturing and is used to make a multitude of everyday items. This process creates plastic parts with complex shapes with precision, consistency, and cost. We encounter and interact with a myriad of injection-molded components all day, every day, even if we don’t ...

READ MORE -

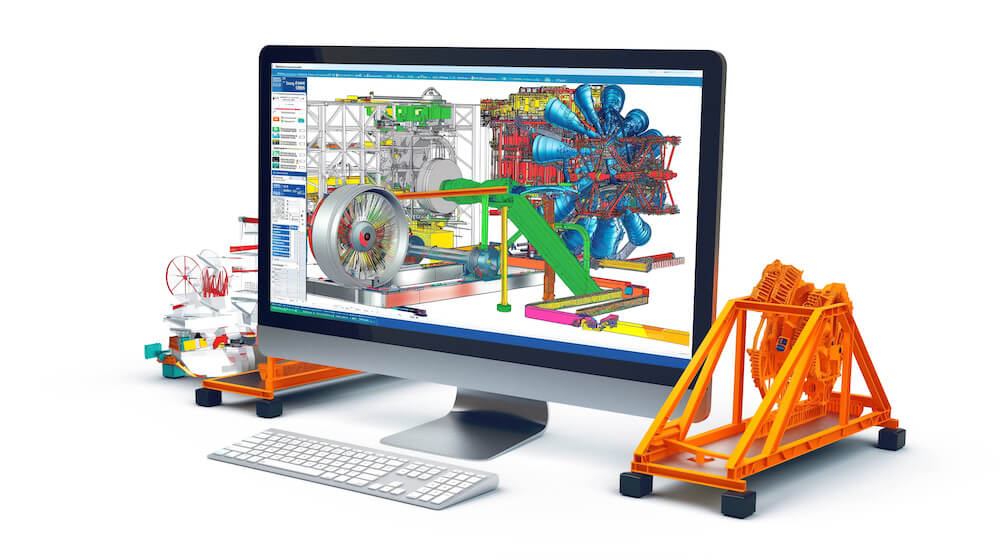

How to Effectively Communicate Your Plastic Product Idea to an Injection Molding Company for Prototyping

Effectively conveying your plastic prototype requirements to an injection molding company is essential for success. Our experts at Protoshop will walk you through the process in this guide, ensuring your vision is accurately translated into a high-quality prototype. Preparing Your Product Idea Before reaching out to an injection molding company, ...

READ MORE -

A Guide to Turning Your Plastic Product Idea into a Mass-Produced Product

Bringing a new plastic product idea to life can be exciting yet challenging. Taking an initial concept and transforming it into a tangible, mass-produced product involves creativity, strategic planning, and perseverance. While launching a successful new product is ultimately rewarding, it requires navigating many critical stages—from early design and prototyping ...

READ MORE -

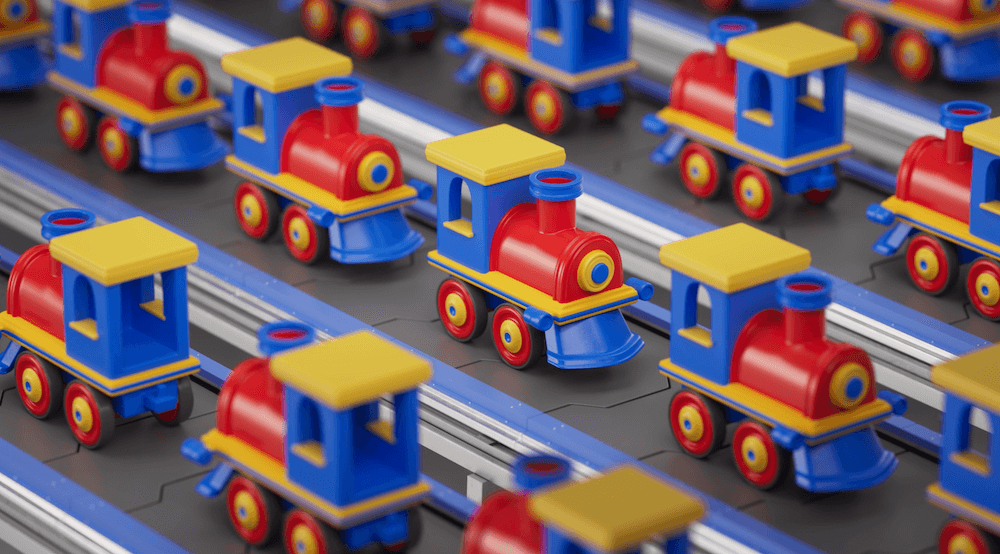

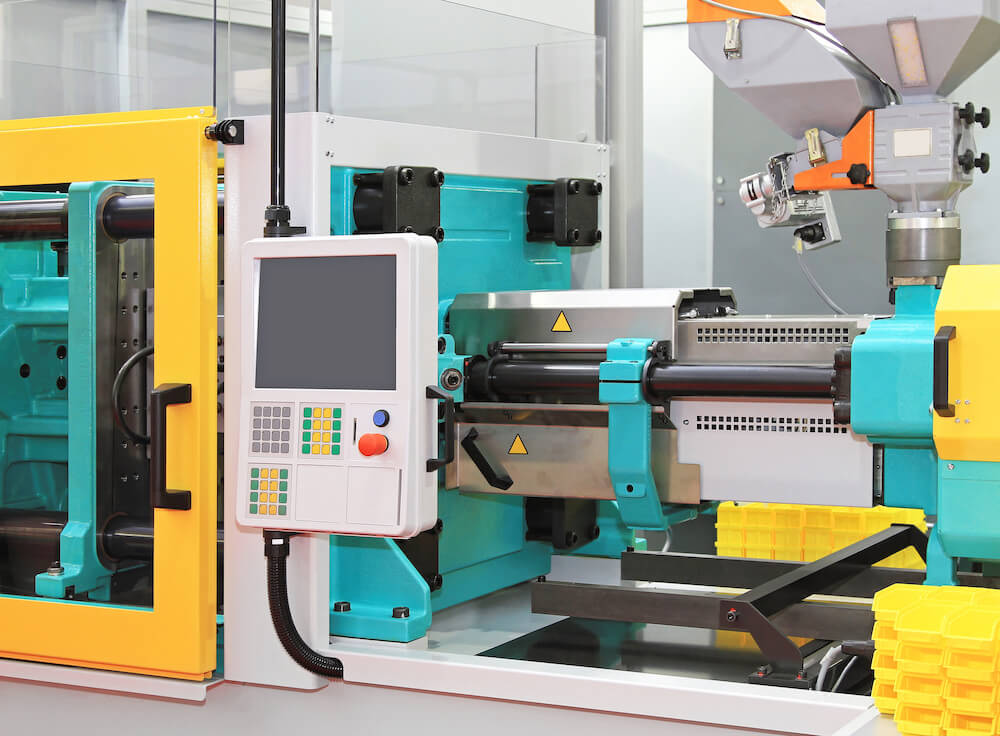

Comprehensive Breakdown of Plastic Injection Molding Machinery

Plastic injection molding is the most efficient and cost-effective way to produce plastic parts with complex geometries. The process involves injecting molten plastic material at high pressures into a mold cavity, which cools and hardens into the final part. From household items and consumer goods to medical devices and automotive ...

READ MORE -

Understanding Plastic Regrind in Injection Molding: Benefits and Applications

A popular method for achieving efficiency and reducing waste in plastic injection molding is the use of regrind. Below, we explore the plastic regrind process, its benefits, and important considerations to using these recycled materials. What is Regrind? Regrind typically refers to the practice of recycling plastic waste generated from ...

READ MORE -

Complex Injection Molding with Geometry for Prototyping: Core and Cavity Integration Strategies

Injection-molded parts are growing increasingly complex in design to meet demanding product requirements. Complex geometries with intricate features push the boundaries of mold technologies. Undercuts, thin walls, and unconventional shapes that would be impossible or impractical to mold using standard techniques are becoming more common. While complex designs allow products ...

READ MORE -

Challenges and Considerations When Using Recyclable Materials in Injection Molding

As industries like Protoshop strive to reduce the environmental impact of waste plastic, the use of recyclable materials in prototype injection molding must be seriously considered. While the benefits of using recyclable materials seem clear, an injection mold with recycled plastic comes with its own set of unique challenges. Types ...

READ MORE