As the industry of product design evolves, innovation and efficiency have become more significant. Prototype injection molding offers designers flexibility, speed, and precision in bringing their concepts to life. In this comprehensive guide, we embark on a journey to understand prototype injection molding, equipping product designers with a robust toolkit for success.

Understanding Prototype Injection Molding for Product Designers

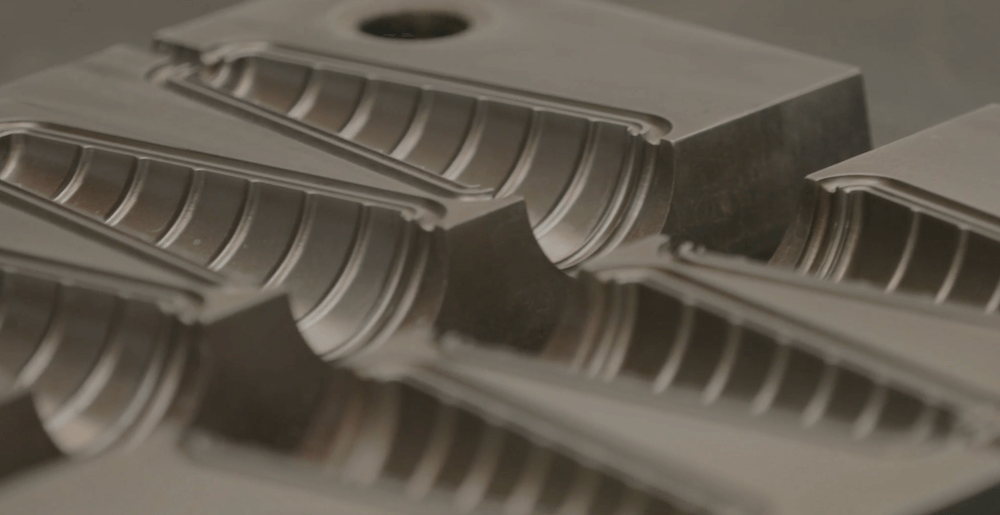

Prototype injection molding allows designers to iterate on designs and swiftly validate concepts with precision. At its essence, this process is identical to injection molding used for production-quality plastic parts in that it involves injecting molten material into a custom-designed mold cavity, where it solidifies to form the desired part. The difference lies in the tool’s construction and the speed with which the tool can be fabricated and modified to facilitate design changes.

The benefits for product designers to use prototype injection molds during product development are manifold, from accelerated development cycles to cost savings and enhanced design flexibility. However, navigating the nuances of prototype injection molding requires a deep understanding of the process, including common misconceptions and pitfalls to avoid.

Selecting the Right Materials for Injection Molding Prototypes

Material selection affects final product performance, durability, and aesthetics. Product designers must carefully evaluate various factors, including mechanical properties, thermal stability, and compatibility with the molding process. Other prototyping methods, such as 3D printing or casting, use materials that do not fully replicate an injection molded part and cannot always flush out design flaws or predict final product performance. By leveraging a prototype tool and molding with a diverse array of materials specifically tailored for injection molding, designers can ensure optimal part performance and functionality while mitigating risks earlier in the design phase.

Design Optimization for Moldability

Design optimization enables designers to streamline the production process and minimize the risk of defects. Incorporating draft angles, maintaining uniform wall thicknesses, and optimizing geometries for smooth mold filling is essential for both prototype and production injection molding. In prototype tools, fine-tuning these important design features is done early. Modifications become very expensive if design changes are needed after multi-cavity, hardened steel production tools are built. Furthermore, leveraging advanced tools and resources for design analysis and optimization, such as mold-flow analysis and finite element analysis (FEA), empowers designers to fine-tune and test their designs for optimal performance, moldability, and efficiency.

Tips and Tricks for a Successful Injection Molding Design

In addition to understanding the fundamentals of injection molding, designers can benefit from incorporating tips and tricks for successful part design, whether for prototype or production-quantity molding.

Seek Early Feedback

Engage with suppliers early in the design process to receive valuable feedback on CAD models, identify potential geometry limitations, and avoid surprises during production. If the design is in flux, prototype tooling partners can collaborate with designers to make the tools modular to incorporate planned future design changes.

Embrace Uniform Wall Thickness

Aim for uniform wall thicknesses between 0.060 and 0.120 inches to ensure even cooling and minimize defects in molded parts. Parts from prototype tools can be used to troubleshoot any design performance or appearance issues before production tools are constructed.

Incorporate Draft Angles

Prototype tools can find issues with tool designs early in the process, such as parts sticking in the mold due to the insufficient draft. Integrate draft angles early in the design process to facilitate smooth part ejection from molds, minimizing stress on parts and molds and reducing the risk of costly delays.

Keep It Simple

Once the mold closes and the molten plastic has been injected, the mold opens, and the part must be ejected from the mold cavity. Any part feature that cannot be formed by the two halves of the mold or prevents the part from being ejected must be formed by other means. Production tooling requires additional mechanisms, such as lifters, side pulls, or rotational mechanisms, so that the part can be removed from the mold. These additional axes of pull increase the mold’s cost and the molded part price.

For prototype tooling, these side-actions are produced with manually loaded core pins, or “pick-outs,” which are ejected with the part and then manually stripped. Clever designers can achieve features like snaps and undercuts through part design rather than relying on complex molds to form complex geometry.

Incorporate Radii

Incorporate radii into designs to reduce shear and turbulence caused by sharp corners, facilitating better fill and stronger parts. Larger radii mean that the cutting tools that form the mold geometry can be bigger, resulting in faster CNC cutting time, thus reducing mold lead time and fabrication cost.

Collaborate Effectively

Forge productive partnerships with prototype injection molding services, communicating openly and transparently to align project objectives, manage timelines, and ensure successful outcomes. Relay uncertainties in the design and possible future changes so that the mold can be designed to incorporate these potential changes.

Working with Prototype Injection Molding Services

Collaborating with prototype injection molding services is essential for product designers seeking to leverage the full potential of this transformative technique. Identifying the right service provider entails thorough research, evaluation, and communication. Designers can forge productive partnerships that yield exceptional results by fostering open communication and transparency.

Contact Protoshop for Your Prototype Injection Molding Needs

Prototype injection molding offers product designers a powerful toolkit for innovation and success. By understanding the nuances of the process, selecting the right materials, optimizing designs for moldability, and collaborating effectively with molding services, designers can unlock new possibilities and propel their projects forward with confidence. As we look to the future, there are many opportunities for those who understand how to use prototype injection molding as a catalyst for innovation and progress.

Protoshop is not just a prototype injection mold and molded parts fabricator; we are development partners. We pride ourselves on our engineering expertise, exceptional customer service, and willingness to take on challenging projects that other shops won’t. Contact us today to get expert assistance on your next project.