Developing prototypes is a pivotal phase in new product development. Prototype parts provide the first tangible models to evaluate ergonomic design attributes, conduct engineering tests to validate strength and function, refine specifications based on physical rather than virtual models, and gather direct customer feedback on potential products. Thorough evaluation at the prototype stage minimizes risk before large investments in production tooling, manufacturing capacity, and market launch activities.

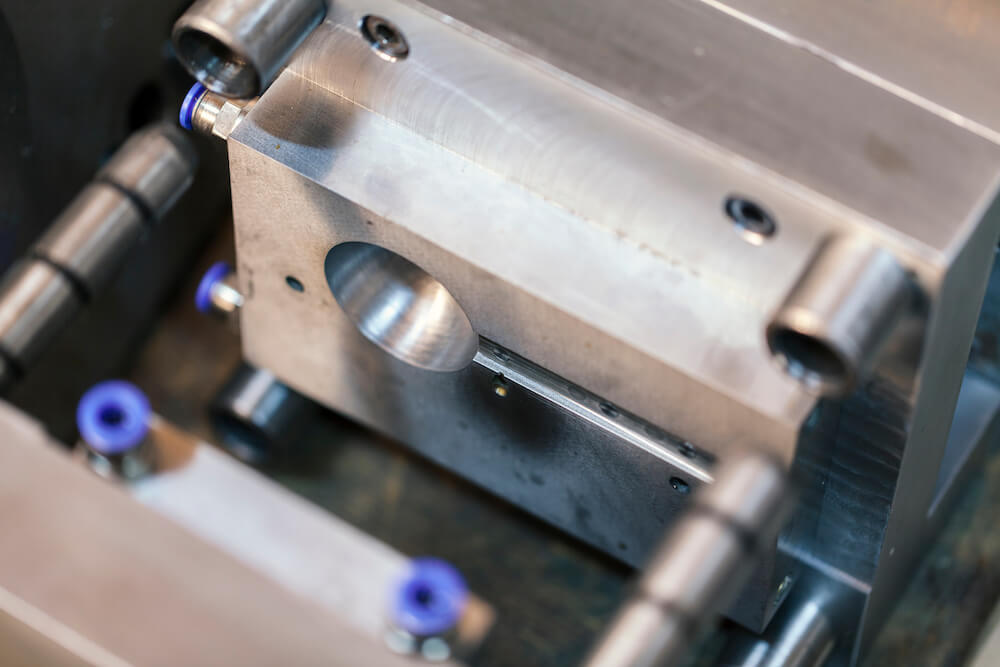

Prototype injection molding produces a limited number of plastic parts using soft tooling for testing form, fit, and function before committing to hardened production tooling. Prototype molds are designed to provide parts quickly and cost-effectively in the new product development process.

These prototype injection molds are typically built from aluminum rather than tool steel to facilitate faster machining and adjustments and revisions as needed. They may utilize components with finished surfaces to shorten lead times where aesthetic appearance permits. Cooling systems are simplified or omitted since mold longevity with moderate run sizes is not required. Still, these molds are robust enough to produce tens of thousands of parts, depending on plastic part geometry.

The prototype molding process replicates the actual production part molding conditions closely. Pre-production plastic resin, molding machines, and parameters are identical to those intended for full-scale production. This yields prototype parts for realistic testing of the proposed design and commercial manufacturing process.

The insight gained from injection molded prototypes is invaluable despite the limited production run quantities. Prototype molding provides vital physical confirmation to confidently advance a product from concept to completed design ready for high-volume manufacturing.

Rapid Iteration of Product Designs

The quick turnaround time for prototype molds, often just a few weeks, allows multiple design concepts to be tested simultaneously. Different design iterations exploring various part geometries, features, and dimensional variations can be molded and evaluated. Prototype tooling also facilitates material testing by enabling samples of many formulations and grades of plastic resin. The ability to rapidly test these physical designs and material variations aids in selecting the optimal solution.

Identify and Fix Issues Early On

Once initial prototypes are molded, design issues can be identified early in development, while changes are still relatively easy to implement. Common defects like sink marks, warpages, or surface defects point to improvements needed in part design or molding parameters. Making adjustments at the prototype stage can prevent costly production delays.

Refine Product Specs and User Experience Faster

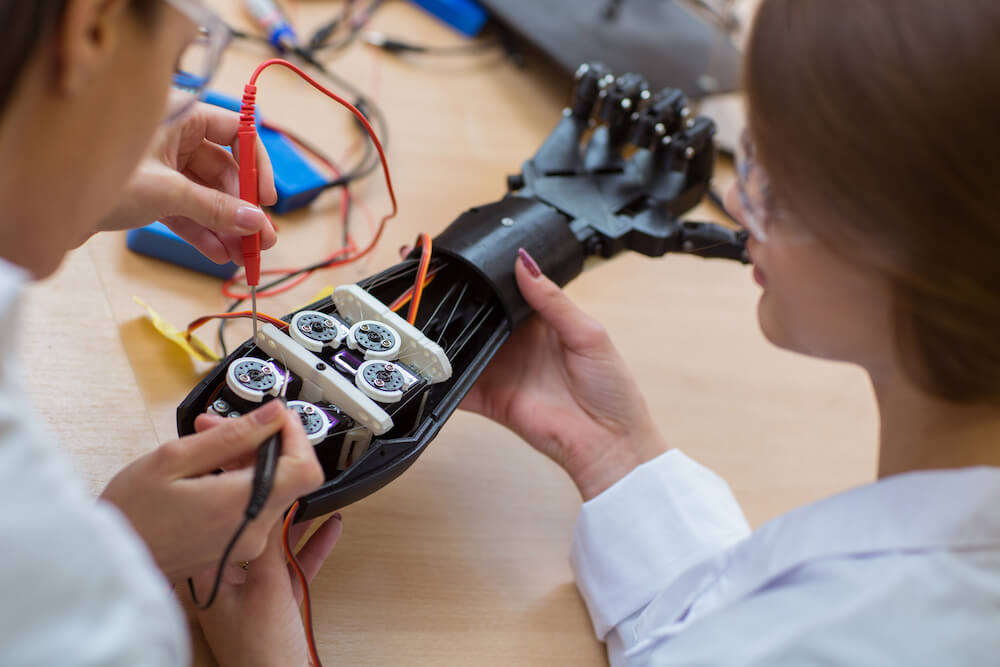

With actual parts in hand in the early phases of development, designers gain valuable insights that assist in refining specifications, functionality, and end-user experience. Getting prototypes to customers for feedback provides real-world input to prioritize refinements. The ability to quickly iterate functional performance and ergonomics based on testing data ultimately leads to products better optimized for their intended use.

Enable Thorough Product Testing

The parts produced with prototype molds provide the first tangible components to verify and test key product functionality. Critical performance attributes and specifications around strength, precision, speed, efficiency, and more can all be quantified and validated versus design goals. This testing provides crucial data to finalize technical requirements before ramping up production.

User Testing and Feedback Studies

Prototypes allow product developers to put working models in the hands of target customers for direct testing and feedback. Observing real customer usage often reveals unforeseen issues that are not detectable through internal testing alone. User studies generate objective data to prioritize refinements and optimizations for maximum usability and customer satisfaction.

Durability Testing under Real-World Conditions

Molding prototype parts in the actual production resin enables physical testing to simulate real-world operating conditions. Prototypes can be subjected to various environmental exposures, mechanical stresses, fatigue testing, and accelerated life cycle testing to ensure the achievement of target service life with an adequate safety margin. This confirmation of durability requirements reduces field failure risks.

Support Manufacturing Planning

The prototype molding stage is a trial run for the materials, machines, tools, and methods required in mass production. Prototype parts validate the planned production processes, equipment, and quality procedures to minimize launch issues. Refining manufacturing and assembly processes with prototypes avoids costly mistakes or delays when ramping up volume later.

Develop Assembly Methods and Quality Controls

Prototype parts facilitate the creation of assembly methods, jigs, and fixtures to evaluate manufacturability. Quality control procedures can also be established for part acceptance, inspection criteria, testing processes, and other protocols. Personnel training needs are identified earlier. Smoothing out assembly and quality control methodology with prototypes prevents hurried efforts later under mass production pressures.

Identify Potential Manufacturing Issues Sooner

Potential production issues not detectable through CAD files alone are frequently uncovered with prototype parts in hand. Prototyping reveals concerns with part tolerance stack-ups, interference fits, assembly sequencing, and other manufacturability issues before production tools are finalized. Identifying these process risks earlier prevents problems when high-volume production is underway.

Reduce Overall Risk and Cost

The low cost of prototype molds, often a fraction of production tools, allows validation of product designs with less financial risk. Companies can utilize prototypes to evaluate technical and commercial viability more prudently rather than sinking costs into full manufacturing capabilities upfront when uncertainties are highest.

Make Informed Go/No Decisions Earlier

Thorough prototype testing yields the necessary data to make informed decisions on further investment in the product. By revealing issues earlier, companies can objectively determine whether to proceed further, modify designs, or terminate projects if warranted. This prevents wasting additional resources on products later found to be flawed.

Avoid Costly Redesign Delays Later On

Design flaws that are undetected until after production tools are built often necessitate substantial rework costs, production delays, and market launch postponements. The prototype confirmation stage significantly reduces the likelihood of these costly late-stage issues by thoroughly vetting designs. Smoother production ramp-up lessens budget overruns.

Incorporating prototype molds in the development process mitigates risk, prevents unnecessary spending, and reduces delays for plastic products. This leads to lower overall development costs.

Choosing the Right Prototype Partner

Selecting the right prototype molding collaborator is critical to maximize value during new product development. Key attributes to evaluate include:

- Seeking broad in-house capabilities aligning with program needs rather than outsourcing steps. Micro molding for tiny, complex parts, rapid tooling for extreme lead time reduction, and similar specialized processes ensure prototyping service breadth.

- Looking for a robust understanding of the full development sequence from early concept reviews to pilot production planning. This big-picture view brings valuable guidance on optimizing the prototyping phase.

- Engaging a partner offering extensive design for manufacturability analysis before tools are cut. Simulation of mold filling, tolerance reviews, gate location recommendations, and component optimization improves outcomes.

The right strategic prototyping ally combines a creative solutions mindset with tactile manufacturing knowledge and project management experience to elevate product development practice. Treat the partner relationship as an integrated, collaborative team effort.

Partner with The Experts at Protoshop for All Your Prototyping Needs

Accelerate your next product development project with Protoshop as your prototype injection molding partner. Leading companies trust Protoshop’s expertise in low-volume aluminum molding and rapid prototyping to test innovative designs quickly and cost-effectively. Whether you need 10 or 10,000 parts, our skilled technicians and precision machines guarantee high-quality pre-production components on accelerated schedules.

Contact us today to discuss your next project and discover how our rapid prototyping expertise can accelerate your product launch timeline.