Understanding the differences between prototype and production molding can be a game-changer in your product development process. Most think that to have production-equivalent plastic parts, you need to build an expensive, long lead-time, hardened-steel production mold and that this can only happen at the end of the product development process when the design is frozen and production-ready.

This is simply not the case. Just like 3D printed parts have accelerated the product development process, so too can prototype plastic injection molding drastically improve speed to market, de-risk product failures, and speed up design iterations. Prototype injection molding has progressed. Such plastic parts can be produced quickly at various critical decision points at any point in the design process with lower-cost prototype molds and injection molded parts. When 3D prints have progressed the design as far as it can go, prototype plastic injection molding can produce parts with geometry and material properties identical to production parts, provide the ability to get a head start on design verification and validation testing, and yield cost savings for higher quantities for pilot runs.

First, What is Production Injection Molding?

Injection molding is a process for efficiently creating large volumes of identical plastic parts. The principle of injection molding is very simple. Plastic material is heated until it becomes a viscous melt and is forced into a closed mold that defines the shape of the article to be produced. There, the material is cooled until it reverts to a solid, then the mold is opened, and the finished part is extracted.

When a product design has been proven, and there is high confidence that the design will not change, production tools are machined from ultra-hard tooling steel. The hard metal reduces metal wear as the metal heats and cools, and parts are molded and ejected from the mold over tens or hundreds of thousands of times.

When machining injection molds in hardened metals, only small amounts of metal can be removed with each tooling pass, or the cutting tools will break. This is the largest driver for the long lead times to create production tooling, which is typically anywhere from 5 to 16 weeks, depending on part geometry. Larger parts with more complexity take longer to machine. Likewise, parts with intricate geometry that require the use of small cutting tools to create the part geometry in the mold cavity will extend the tooling production timeline.

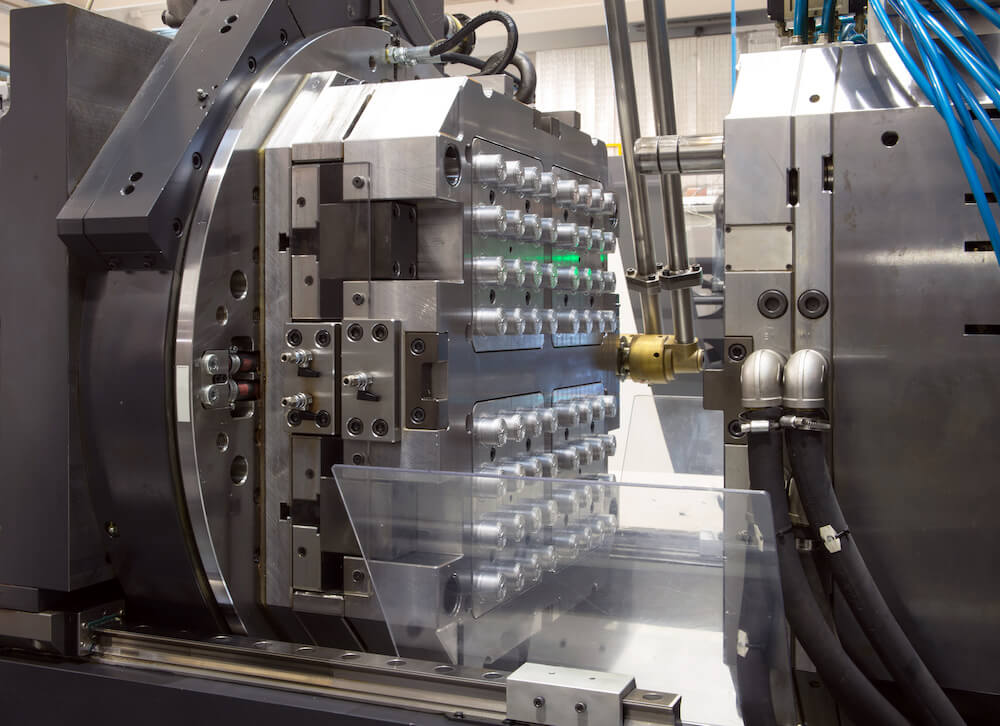

Production molds are sophisticated and complicated. In production tooling, features in the plastic part that can’t be formed with the primary core and cavity halves of the mold require side action mechanisms such as slides and lifters. These mechanisms add additional complexity when multiplied across numerous mold cavities.

Production molds are designed to reduce the cost of the plastic part as much as possible. While the cost of the plastic is a small part of the overall cost of the molded part, the primary driver of cost is the cycle time of the mold. Cycle time includes the time it takes to close the mold, inject the plastic, cool the part in the mold, and open the mold and eject the part. Production molds can produce a number of parts at the same time with short cycle times; molds are typically built with 2, 4, 8, 16, 32, etc. cavities to reduce part costs, and heating and cooling are added to the mold to speed up the phases of molding. If, for example, the cycle time to create a part is one minute, and the cost to run the mold is $2 per minute, a molded part from a single cavity mold would cost $2, and parts from a 4 cavity mold would cost $0.50.

What is Prototype Injection Molding?

Prototype injection molds use the same injection molding materials that are used in production tooling. The difference between prototype and production injection molded parts lies primarily in the construction of the tooling and the number of cavities in the tool.

Prototype molds are typically CNC machined in aluminum or brass; the metal is softer and can be machined more quickly and, therefore, less expensive. While aluminum and brass are less robust than stainless steel over hundreds of thousands of molding cycles, molds constructed in these softer metals will typically still produce tens of thousands of parts before the tool wears and, depending on geometry, can produce many more without sacrificing dimensional accuracy over the life of the tool.

Prototype injection molding tools are typically single cavities by design, making it easier to make changes to fine-tune the part geometry. If, after molding parts and testing, a change to the part is needed, only one cavity needs to be modified. Metal-safe and non-metal-safe changes can be accommodated. A metal-safe change means that the part change adds plastic to the part, and the mold is altered by removing metal from the mold. If the change requires adding metal to the mold (removing plastic from the part), prototype tooling is easier to change than production tooling constructed of harder metal with multiple cavities; a pocket is cut into the mold, a plug is pressed into the pocket, and the new geometry is machined. Tools constructed with hardened tool steel must be welded to add material to the mold for non-metal-safe changes.

Prototype injection molded tooling does not employ automated mechanisms for features in the part that are not in line with the direction of the mold opening. In prototype tooling, these features are created with components (called core pins or pickouts) that are manually loaded into the injection molding cavity and, when the part is molded and ejected from the mold, are ejected with the part. The operator must then manually strip these core pins from the part. The simpler design drastically reduces the cost of the prototype mold as compared to a production mold but increases the cycle time and, thus, the part cost.

Most prototype molds don’t employ heating and cooling, so the cycle times are longer, and it requires personnel who really know what they’re doing to get the part to fill properly.

When to choose prototype tooling over production tooling:

- Parts are needed very quickly

- The design is not finalized, and changes are anticipated.

- Multiple materials are being considered that require testing

- A critical design feature requires iteration to get right (e.g., snaps, seals)

- 3D prints have outlived their usefulness, or printed features are not adequately robust

- Testing needs to be performed on production equivalent parts (e.g., medical devices)

- Rubber-like materials are involved (TPE, TPU) for seals or grip

- Low volumes of parts are required for user trials

- Overmolded or inserted prototype parts are required

- Final production quantities don’t justify expensive production tools

FAQs in Relation to Differences Between Prototype and Production Molding

What is the difference between production and prototype?

A prototype is a preliminary model used for testing, while production refers to the final product made in large quantities after successful prototyping.

What is the difference between prototype and production parts?

Prototype parts are created for validation and testing during early design stages. Production parts, on the other hand, are final components produced in bulk following approved designs.

What is the difference between a prototype tool and a production tool?

A production tool is designed for high-volume manufacturing and is constructed from hardened tool steel. A production tool may have automated slides for side action and multiple cavities. A prototype tool is fabricated in aluminum or brass for short-run manufacturing or concept validation, has hand-loaded core pins, and typically single cavity.

What is prototype molding?

Prototype molding is plastic injection molding using a prototype tool.

Protoshop Can Help You With Your Injection Molding Needs

Protoshop Inc. uses steel mold base frames with detail cut into softer metal inserts. This translates to tooling that can produce up to 100K parts, yet is easily modifiable should the part geometry require changes, even non-metal safe changes. Iterations typically occur within a day.

Fabrication:

Single-cavity prototype mold fabrication can occur in one week, not several weeks or months. The plastic injection molded parts produced by this tooling can be used for user testing, plastics joining refinement, functional testing, and other part validation activities in advance of investment in production tooling.

Risk Mitigation:

Prototype tooling mitigates scale-up risk and is inexpensive to fabricate; typical costs are $6K to $15K, depending on part complexity and size.