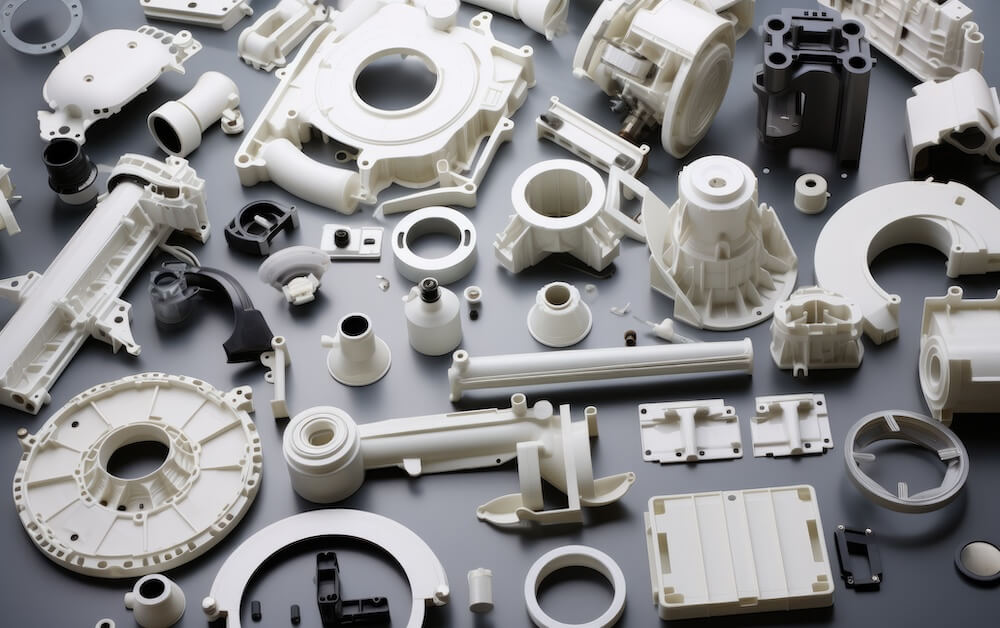

Savvy businesses rely on rapidly produced prototype injection-molded parts to innovate and efficiently bring new products to market. While these molds can produce thousands of parts (even tens of thousands), they are not nearly as durable as production molds. Factors such as tooling material, design complexity, and maintenance practices affect tooling longevity and, ultimately, the number of parts that can be produced.

Material Selection and Its Impact on Tooling Lifespan

The most significant contributor to mold durability and performance is the choice of material from which the mold is built. Aluminum, in particular, is a popular choice for prototype molds due to its distinct properties that cater to the demands of rapid prototyping.

Benefits of Aluminum in Injection Molding

- Thermal Conductivity: Aluminum has excellent thermal conductivity. This facilitates faster heating and cooling cycles during the injection molding, reducing molding cycle times and increasing production efficiency.

- Machinability: Aluminum is easy to machine compared to harder metals. This reduces cutting tool wear and increases cutting speed, making the mold less expensive and fabrication faster.

- Cost-Effectiveness: Aluminum is typically less expensive than other tooling materials, making it a cost-effective option for prototype tooling, especially when the production volume is relatively low.

- Reusability: Aluminum molds can be easily modified for design iterations, providing flexibility and efficiency in prototyping.

Limitations of Aluminum in Injection Molding

- Wear Resistance: Although aluminum molds are suitable for low—to medium-volume production runs, they may exhibit faster wear than steel molds, especially under high-volume production conditions.

- Strength: While aluminum is strong enough for prototype tooling, it is generally less durable than steel, which may limit its use in molding small, thin features.

Steel offers greater wear resistance and can withstand higher mold cycle volumes, but it is more challenging to machine and, therefore, more costly. Conversely, resin tooling materials may provide quicker turnaround times and lower costs but lack the mechanical strength, accuracy, and thermal stability of metal molds.

The choice of aluminum for prototype tooling offers a balanced mix of efficiency, cost, and performance. It is particularly suitable for rapid prototyping scenarios where speed, accuracy, and flexibility are the most important parameters. However, the selection must be aligned with the project’s specific needs, considering factors such as the anticipated production volume, the part’s complexity, and the mold’s required durability.

The Influence of Part Geometry on Mold Robustness

Molded part geometry also plays a role in determining the robustness and longevity of prototype tooling. The complexity of the design, including the shape, size, and features of the part, directly influences the stress and wear of the mold during the molding process.

Complexity and Mold Wear

- Intricate Features: Parts with complex geometries, intricate details, or undercuts require molds with corresponding complexity, which can lead to increased wear and shorter mold life. Thin and complex features in the mold are more likely to break during ejection.

- Thin Walls: Designs featuring thin walls may require higher injection molding pressures to ensure proper filling and cooling, potentially increasing the stress on the mold.

- Large Flat Areas: Conversely, large, flat surfaces can lead to uneven cooling and thermal stresses, which can impact the mold’s durability.

Design Considerations for Enhanced Durability

- Uniform Wall Thickness: Maintaining uniform wall thickness in the part design can promote more consistent cooling and reduce the likelihood of stress concentrations in the mold.

- Rounded Corners: Incorporating radii instead of sharp edges can help distribute stress more evenly, minimizing the risk of cracks and wear in the mold.

- Draft Angles: Including appropriate draft angles prevents the part from scraping the tool as it is ejected and facilitates the removal of the part from the mold, reducing wear and tear on the tooling. A general rule is to add 1 degree of draft for every inch of feature depth. Shutoffs require 3 degrees of draft, and texture increases draft requirements.

- Gating and Ejection: Properly placed gates and ejector pins can minimize stress on the mold during the injection and ejection phases, enhancing the mold’s lifespan.

By carefully considering these aspects of part geometry in the design phase, manufacturers can create molds that are not only capable of producing high-quality parts but also more robust and longer-lasting.

The Role of Side Action Core Pins in Mold Tool Longevity

Side action core pins are essential in injection molding to create complex parts with undercuts or recesses; they create features that a simple two-part mold cannot achieve. These pins usually move perpendicularly to the mold’s opening and closing direction and add complexity to the mold design, directly impacting the tool’s durability and operational lifespan.

The quantity and design of these side-action slides or core pins in a mold significantly influence their longevity. An increased number of core pins introduces more moving parts and potential friction wear, necessitating more frequent maintenance.

When incorporating side-action core pins, balancing the complexity necessary for part design with mold longevity is key. Proper design and material selection for these pins is vital to distribute stress evenly and minimize wear, extending the mold’s service life while maintaining high production standards. Thoughtful integration of core pins into the mold design ensures detailed part creation without sacrificing tool durability.

Maintenance Practices for Prolonging Mold Tool Life

Proper mold maintenance ensures consistent quality prototypes, extends the service life of the tool, and prevents costly downtime and repairs. Here are some best practices and tips for maintaining aluminum tooling:

Regular Cleaning:

Aluminum molds should be cleaned regularly to remove any residues or particulates that can cause surface imperfections on the molded parts or contribute to the degradation of the mold.

- Clean the molds after each production run to prevent the buildup of polymers and other materials.

- Use appropriate cleaning solutions and techniques that do not damage the aluminum surface.

Lubrication:

Apply suitable mold release agents and lubricants to prevent sticking and reduce wear on the mold surfaces. Proper lubrication also facilitates the ejection process and extends the life of the mold.

Inspection and Monitoring:

Regularly inspect the mold for signs of wear, damage, or alignment issues.

- Conduct visual inspections for scratches, dents, or corrosion.

- Monitor mold performance and part quality to identify any potential issues early.

Timely Repairs:

Address any detected issues promptly to prevent them from escalating into more significant problems.

- Repair or replace damaged or worn components immediately to maintain mold integrity and performance.

- Ensure repairs are carried out by qualified personnel using appropriate tools and materials.

Proper Storage:

Store the molds in a controlled environment to protect them from moisture, dust, and temperature fluctuations when not in use.

- Use protective covers to shield the molds from environmental factors.

- Maintain an organized storage system to prevent accidental damage.

By implementing a structured maintenance routine, businesses can ensure their molds remain in optimal condition, delivering consistent performance and minimizing the need for unexpected repairs or replacements.

Ensuring Longevity in Prototype Tooling with Protoshop Inc.

At Protoshop Inc., we pride ourselves on our profound insight into the critical elements that define the success of prototype tooling and our unwavering commitment to excellence. Our specialized knowledge in selecting the right materials, optimizing designs, and offering comprehensive mold maintenance makes us an essential ally for businesses aiming to enhance the efficiency and lifespan of their prototype tooling and injection molded parts. Partnering with Protoshop Inc. means tapping into a reservoir of expertise and experience, guaranteeing that your prototype injection molding tooling is finely tuned for maximum durability and optimal performance.