-

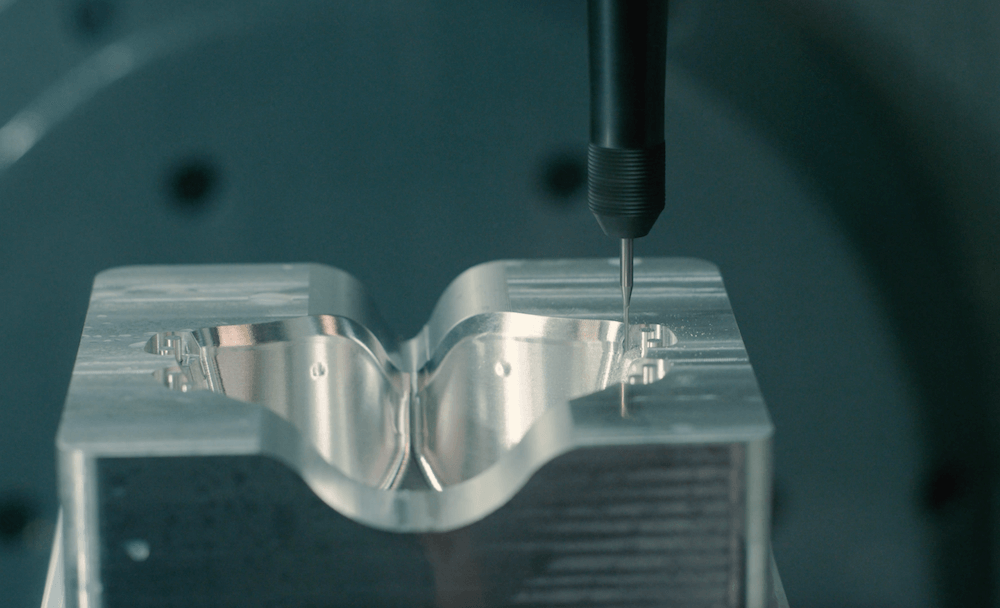

Complex Injection Molding with Geometry for Prototyping: Core and Cavity Integration Strategies

Injection-molded parts are growing increasingly complex in design to meet demanding product requirements. Complex geometries with intricate features push the boundaries of mold technologies. Undercuts, thin walls, and unconventional shapes that would be impossible or impractical to mold using standard techniques are becoming more common. While complex designs allow products ...

READ MORE -

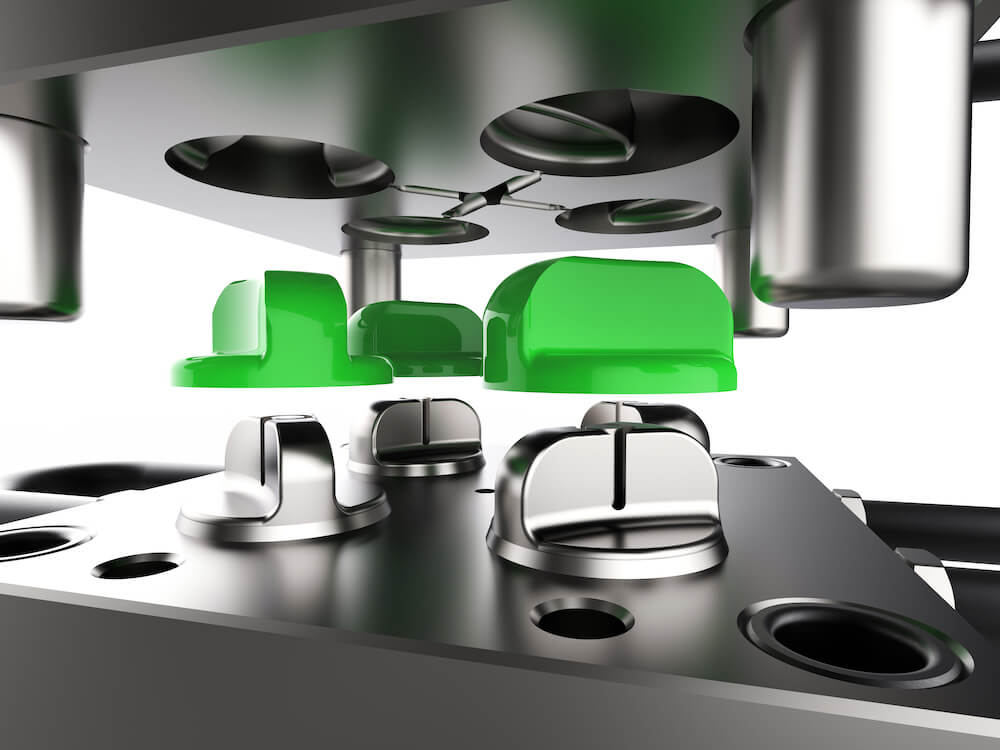

Cost-Effective Injection Mold Fabrication: Balancing Quality & Budget

The quality of an injection molding tool directly impacts product quality and overall production costs. Balancing the need for high-quality molds with budget constraints is a challenge product developers and manufacturers contend with continually. Strategies for achieving cost-effective mold fabrication without compromising quality will maximize the value of an injection ...

READ MORE -

Prototype Injection Molding: Choosing the Right Material for Your Project

Prototyping is a critical step in the injection molding process for product design and development. Creating prototypes allows designers to test concepts, evaluate functionality, refine designs, and minimize risk before investing in production tooling. Prototype injection molding offers many benefits over other prototyping methods when it comes to simulating the ...

READ MORE -

Prototype Injection Molding Process Guidelines

A Guide to Prototype Injection Molding Prototype injection molding is a manufacturing process that involves creating a physical plastic prototype or sample of a plastic product using injection molding techniques. It is a highly versatile and efficient method of producing small quantities of complex plastic parts with precision and speed. ...

READ MORE -

Plastic Part Manufacturing Costs

Plastics are a very good fit for manufacturing and their use becomes, even more, cost-effective as volume increases. Plastics are used to fabricate products in every major industry such as medical, automotive, electronics, housewares, etc due to their cost advantages. Besides cost, plastics are often used in high-volume manufacturing due ...

READ MORE