-

How Tariffs Are Changing the Plastic Injection Molding Industry

Global instability and newly imposed international tariffs have the potential to disrupt the global manufacturing industry. Among the hardest hit industries is plastic injection molding, a critical component in the prototyping and production of plastic parts across industries like automotive, consumer electronics, medical devices, and industrial equipment.With tariffs on imported ...

READ MORE -

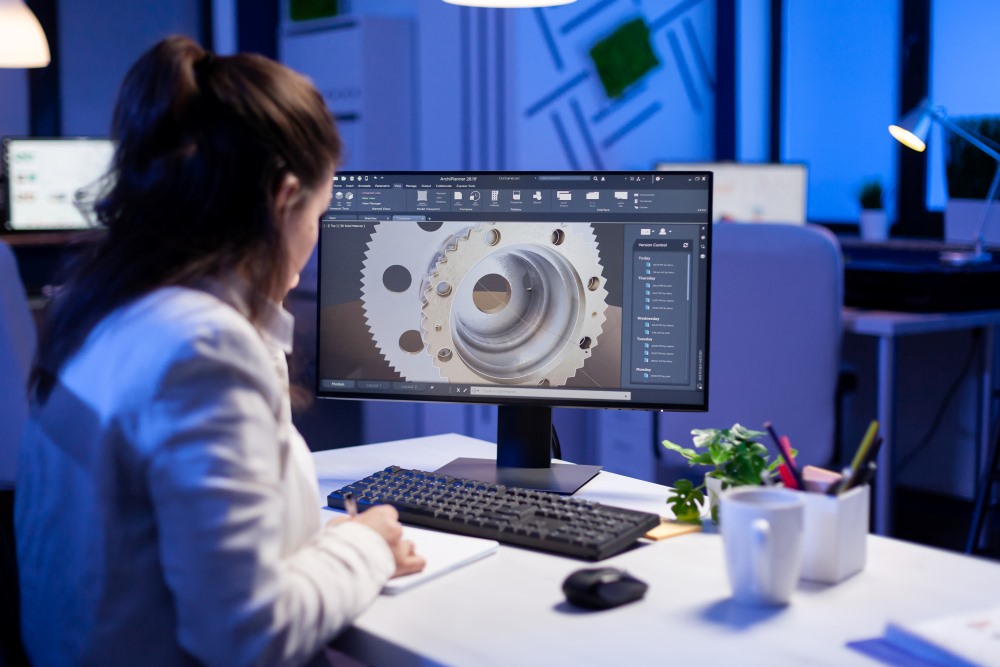

How Injection Molding In the Automotive Industry Helps with High-Performance Lightweight Parts

In the automotive industry, injection molded parts can improve vehicle performance, fuel efficiency, and sustainability by balancing the need for strength, weight reduction, and cost-effectiveness. Protoshop provides rapid prototype injection molding and tooling solutions to help the automakers stay ahead of the curve. Why Lightweight Parts Matter in the Automotive ...

READ MORE -

Exploring Various Techniques for Post-Molding Operations

Plastic injection molding is highly effective at producing near-net-shape parts, but additional steps are often needed to achieve a part’s final requirements. Post-molding operations refer to any processes performed on a molded part after it’s ejected from the mold, in order to impart the final shape, features, or finish. These ...

READ MORE -

A Simple Guide to Cycle Time For Injection Molding

Cycle time is a key metric in plastic injection molding that affects efficiency, cost, and quality. For companies that fabricate rapid molds for injection molding prototypes, like Protoshop Inc., optimizing cycle time and part cost may not be the primary goal but should be considered early in the design phase ...

READ MORE -

Common Mistakes to Avoid When Designing Plastic Prototypes for Injection Molding

Precision plastic prototyping ensures success when transitioning to full-scale injection molding production. Even small oversights or mistakes in the design phase can lead to significant issues down the line, from part defects and quality problems to production delays and increased costs. By understanding common pitfalls and missteps early in the ...

READ MORE -

Everyday Plastic Products That Are Injection Molded Parts

Plastic injection molding is the backbone of modern manufacturing and is used to make a multitude of everyday items. This process creates plastic parts with complex shapes with precision, consistency, and cost. We encounter and interact with a myriad of injection-molded components all day, every day, even if we don’t ...

READ MORE