Rapid prototyping has become an invaluable tool for companies looking to accelerate development and quickly bring new products to market. In technology, manufacturing, and consumer goods, getting products to customers ahead of the competition is critical.

By prototyping early in the process, companies can test and find design problems before full production. This early feedback allows for continuous refinement, as well as more robust and functional designs. Prototypes can be iterated faster, and get to market quicker and more efficiently.

Leveraging rapid prototyping during the design phase can provide significant advantages.

What is Rapid Prototyping?

Rapid prototyping refers to a range of additive manufacturing techniques that quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. In rapid prototyping, prototype models are constructed by adding material layer-by-layer using 3D printing or additive manufacturing technologies.

Efficient Product Design Testing with Rapid Prototyping

Rapid prototyping is commonly used in product development and manufacturing to allow developers and engineers to quickly test and iterate on designs before full-scale production. It is an efficient method to evaluate a part design’s form, fit, and functionality without the time and expense required to engineer hard tooling. Rapid prototypes can provide valuable feedback regarding the design earlier in the design cycle.

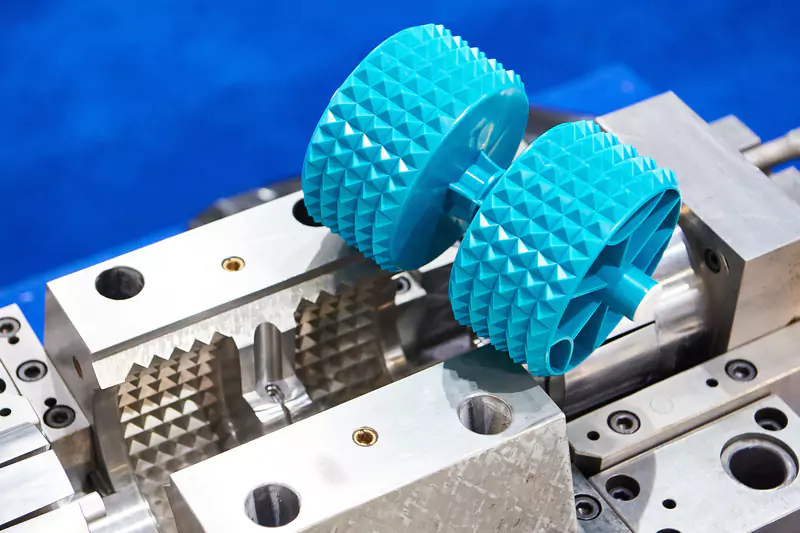

Prototype injection molding tools can be used to create injection molded parts before committing to production tooling. Producing functional rapid prototype injection molds and parts enables validation of the mold design as well as verification of plastic part design details like wall thickness, draft angles, ejection, and more. This process helps ensure high-quality final production tools and molded components.

Rapid Prototyping vs. Traditional Prototyping

There are a few key differences between rapid prototyping and traditional prototyping methods:

- Speed: Rapid prototyping using additive manufacturing technologies can create a prototype in a matter of hours or days rather than weeks. This faster turnaround time enables more design iterations.

- Cost: Rapid prototyping tends to have lower costs than traditional CNC machining prototypes. No hard tooling is required, reducing setup costs.

- Design flexibility: Design changes are easier to implement with rapid prototyping. CAD models can be quickly modified, and new iterations can be printed without reproducing hard tooling.

- Limitations: Traditional methods may still be required for functional prototypes. Additive methods are limited by minimum feature size, surface finish, and choice of materials. These limitations are where Protoshop’s injection molding services come into play.

Rapid prototyping is best leveraged early in the design process when form and fit are being evaluated. As the design matures, traditional prototyping or production-intent processes are used to create fully functional prototypes and pre-production versions.

Rapid Prototyping Process

The process of creating a rapid prototype generally follows these main steps:

Step 1: CAD Model Design

The first step in rapid prototyping is to create a 3D model of the part or assembly using CAD software. Common CAD programs used include SolidWorks, Autodesk Inventor, and PTC Creo. The designer will model the part geometry and specifications required for the prototype.

Step 2: Convert to STL File

Once the CAD model is complete, it is typically converted into an STL file format. STL stands for stereolithography and is a file format native to 3D printing processes. The STL file approximates the surfaces of the solid model using triangular facets.

Step 3: Transfer the STL File to the Machine

The STL file is then transferred to the rapid prototyping machine through a direct connection or USB drive. The file provides the 3D printer or additive manufacturing machine with the geometric data needed to construct the layers.

Step 4: Layer-by-Layer Construction

Using the STL file, the rapid prototyping machine then starts constructing the prototype layer by layer. The process involves adding liquid, powder, sheet material, or filament and bonding each layer together to build up the prototype. The layers are typically 0.001 to 0.010 inches thick.

Step 5: Cleaning and Finishing

Once construction is complete, the prototype is removed from the machine for any required cleaning, curing, or post-processing. Any support structures are detached. The surface may also be sanded or painted if a higher-quality surface finish is needed.

Step 6: Testing and Analysis

The prototype is now ready for evaluation. Designers and engineers will test the prototype under expected conditions, inspect the part fit, and provide feedback to improve the design in the next iteration. Testing can range from simple visual inspections to more complex functional tests, depending on the prototype’s purpose.

Step 7: Iteration

One of the primary advantages of rapid prototyping is the ability to iterate quickly. Based on the feedback and results from the testing phase, designers can go back to the CAD model, make necessary modifications, and produce a new prototype. This iterative process continues until the design meets the desired criteria.

Types of Rapid Prototyping

Rapid prototyping encompasses a range of techniques that allow for the quick fabrication of physical models from digital designs. Each method has its unique advantages, applications, and materials. Here’s a brief overview of some the various types of rapid prototyping:

Stereolithography (SLA)

Stereolithography is one of the earliest forms of rapid prototyping. It uses a UV laser to solidify layers of photosensitive resin. The process is repeated layer by layer until the model is complete. SLA is known for its high accuracy and smooth surface finishes.

Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered material, binding it together to form a solid structure. It can be used with various materials, including plastics, metals, and ceramics. SLS doesn’t require support structures, making it suitable for complex geometries.

Fused Deposition Modeling (FDM)

FDM works by extruding a thermoplastic filament through a heated nozzle, layer by layer, to build the model. It’s one of the most common and affordable 3D printing methods, suitable for both prototyping and some end-use applications.

Digital Light Processing (DLP)

Similar to SLA, DLP uses a digital light projector screen to solidify photopolymer resin. Instead of tracing the design with a UV laser, DLP exposes an entire layer at once, making it faster than SLA for some applications.

Laminated Object Manufacturing (LOM)

In LOM, layers of adhesive-coated paper, plastic, or metal laminates are successively glued together and cut to shape with a knife or laser. It’s a cost-effective method for creating large models.

Binder Jetting

This method involves depositing a liquid binding agent onto a powder bed to bind the particles together. The process is repeated layer by layer. Once complete, the green part is cured in an oven or with a post-processing technique.

Protoshop’s Rapid Prototyping with Injection Molding

Injection molding is a traditional manufacturing method where molten material is injected into a mold to form parts. This approach allows for the rapid iteration of design changes, testing of different materials, and design validation before moving to large-scale production.

Tools and Methods For Rapid Prototyping

A variety of tools and methods are used in rapid prototyping for plastic injection molding:

CAD Software

CAD programs like SolidWorks, Rhino, or Fusion 360 are essential for designing the part model geometry that will be rapidly prototyped. The CAD model is also used to design any required mold tooling.

3D Printers

3D printers, such as FDM, SLA, or PolyJet, are one of the quickest ways to print plastic components for fit and form testing. Desktop printers provide fast iteration cycles.

CNC Machining

CNC mills and lathes can rapidly machine mold components like cavities, cores, and inserts from soft metal blocks rather than fabricating hard production tooling.

Injection Molding Machines

Small benchtop or prototype injection molding machines can accept simplified mold tooling for lower-volume injection molding of prototype plastic parts.

Vacuum Casting

Silicone rubber molds made from rapid prototypes can be used with vacuum casting processes to produce urethane resin prototype parts without tooling.

A New Age in Rapid Prototyping: Production-Equivalent Parts

Rather than just focusing on producing parts quickly, it’s essential to emphasize the production-equivalence of these parts using injection molding. It means that while the prototypes mirror the speed of 3D printed parts, they are also fully functional and equivalent to what would be achieved in large-scale production. This production parity ensures that the final product isn’t just fast, but also of high caliber.

What are the advantages of choosing prototype injection molding over rapid prototyping?

Deciding whether to use prototype or production tooling depends on several factors. Prototype tooling makes sense when:

- The design is still evolving, and you expect revisions. Production tools lock in a design.

- You need parts extremely quickly. Prototyping is faster for one-off or low-volume parts.

- You want to test different materials before finalizing one. This allows flexibility.

- A critical feature like snaps or seals needs refinement through hands-on iteration.

- 3D printed parts have proven inadequate for durability or detail. You want more robust prototypes.

- Testing requires parts indistinguishable from final production. Like with medical devices.

- The material is rubbery, like TPU or TPE. These can be tricky for 3D printing.

- You need low volumes for user testing. Production tools aren’t worth it yet.

- Insert molded or overmolded parts are needed. Prototyping excels at multi-component parts.

- Production volumes don’t justify expensive production tooling. Prototyping is more economical.

Optimizing Functional Prototypes with Rapid Injection Mold Tooling

Rapid injection mold tooling enables verification of key component parameters on prototypes for more effective prototyping. This provides data to help optimize the performance and quality of the final production tooling and injection molded components. Once printed rapid prototypes have exhausted their ability to instruct the design, injection molding prototypes facilitate an iterative design approach that results in a better final product produced faster and at lower cost.

Protoshop for Rapid Prototyping

Protoshop leverages the power of rapid molds to deliver high-quality prototypes that are production equivalent. Our combination of in-house expertise and capabilities enables us to rapidly produce prototype tooling and injection molded parts to help accelerate your development process.

Rapid Prototyping & Engineering Injection Molding Services

Whether you need 50 or 5,000 parts, Protoshop can meet your rapid prototyping and injection molding needs. Our expert engineers provide complete support from prototype to production. Contact Protoshop today to discuss your next project and request a quote for our rapid injection molding services.