Articles

Speed vs. Quality in Prototype Tooling: Finding the Right Balance

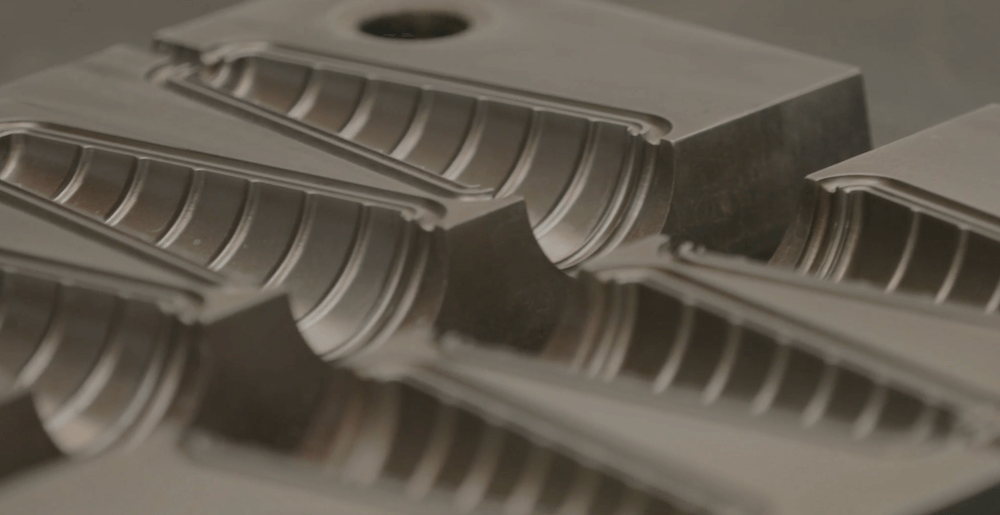

Prototyping is one of the most important steps in the product development process. Prototypes allow product developers to find design flaws and/or test different design options quickly by providing tangible models that can be evaluated for form, fit, and functionality before committing to full-scale production tooling. Different types of prototypes can be used during different phases of the project, including clay mock-ups, 3D printed parts, machined parts, and cast and injection molded parts. Due to advances in the speed of mold fabrication, prototype injection molding has become one of the most popular methods of producing both functional plastic prototypes and

Cost-Effective Injection Mold Fabrication: Balancing Quality & Budget

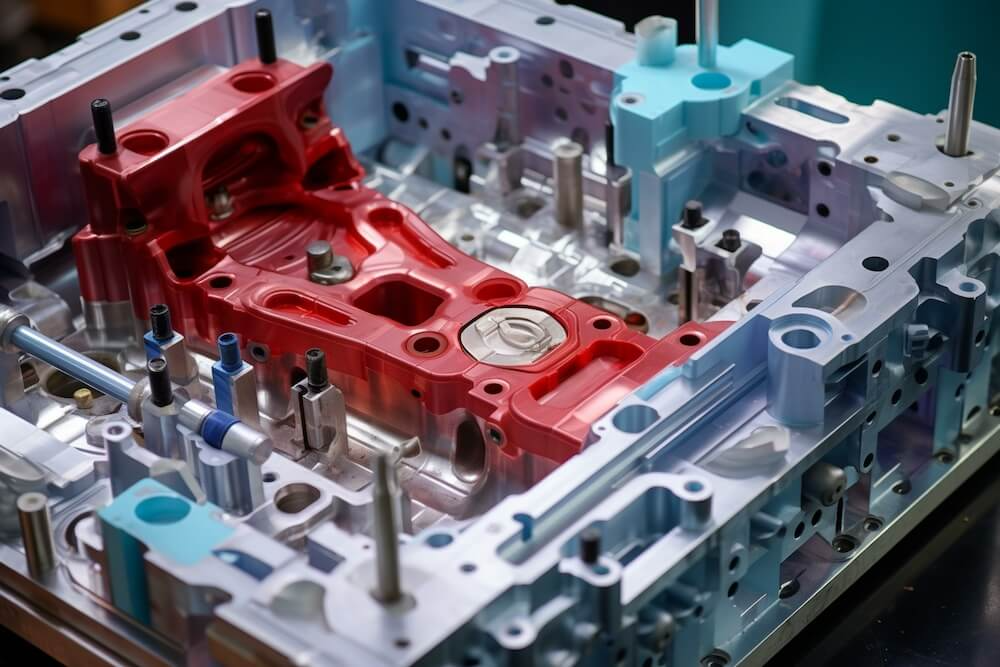

The quality of an injection molding tool directly impacts product quality and overall production costs. Balancing the need for high-quality molds with budget constraints is a challenge product developers and manufacturers contend with continually. Strategies for achieving cost-effective mold fabrication without compromising quality will maximize the value of an injection molding tooling investment. From efficient design practices and leveraging of technology to material selection, we’ll explore practical approaches to help product developers and manufacturers optimize the mold fabrication processes. Understanding the Importance of Quality in Mold Fabrication High-quality molds contribute significantly to product precision, surface finish, and functionality, ultimately enhancing

Protoshop’s Dylann Ceriani on “The Selling Podcast” with Mike Williams and Scott Schlofman

On her guest appearance on The Selling Podcast, Dylann Ceriani, co-founder of Protoshop, chats with hosts Scott Schlofman and Mike Williams, providing a unique sales perspective from the standpoint of an engineer. Though Dylann loves technical work, she has stepped into sales out of necessity and devotion to her position as a new business co-founder. She discusses her lead generation tactics, leveraging LinkedIn and her website to find customers without a sales team. Dylann also clarifies her consultative approach, where she guides potential clients on the best part design for efficient manufacturing. Throughout the episode, Dylann gives an inside look

Prototype Injection Molding for Product Designers: A Comprehensive Guide to Success

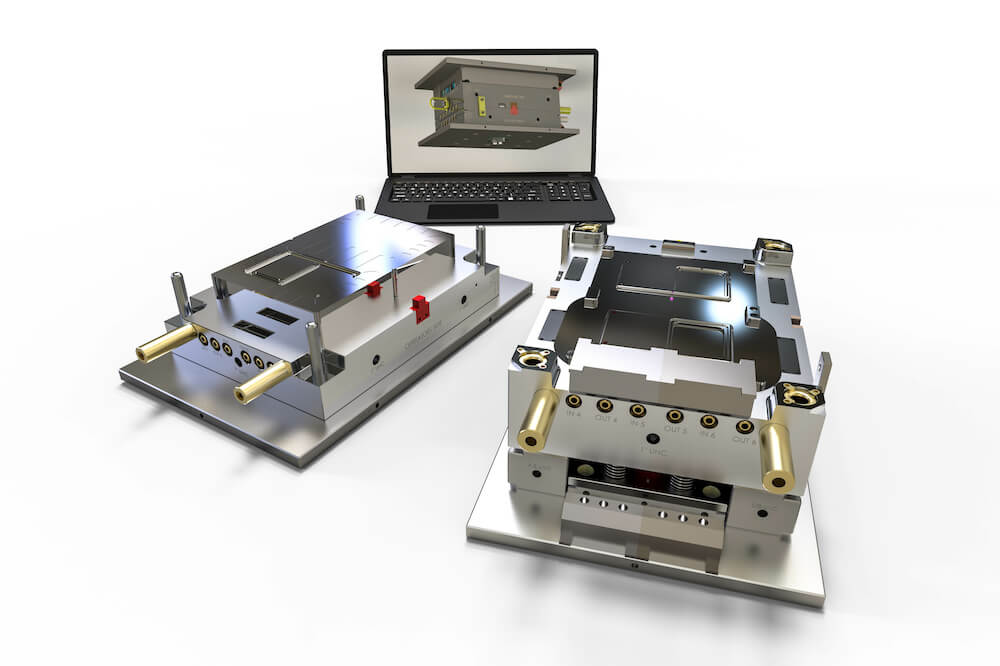

As the industry of product design evolves, innovation and efficiency have become more significant. Prototype injection molding offers designers flexibility, speed, and precision in bringing their concepts to life. In this comprehensive guide, we embark on a journey to understand prototype injection molding, equipping product designers with a robust toolkit for success. Understanding Prototype Injection Molding for Product Designers Prototype injection molding allows designers to iterate on designs and swiftly validate concepts with precision. At its essence, this process is identical to injection molding used for production-quality plastic parts in that it involves injecting molten material into a custom-designed mold

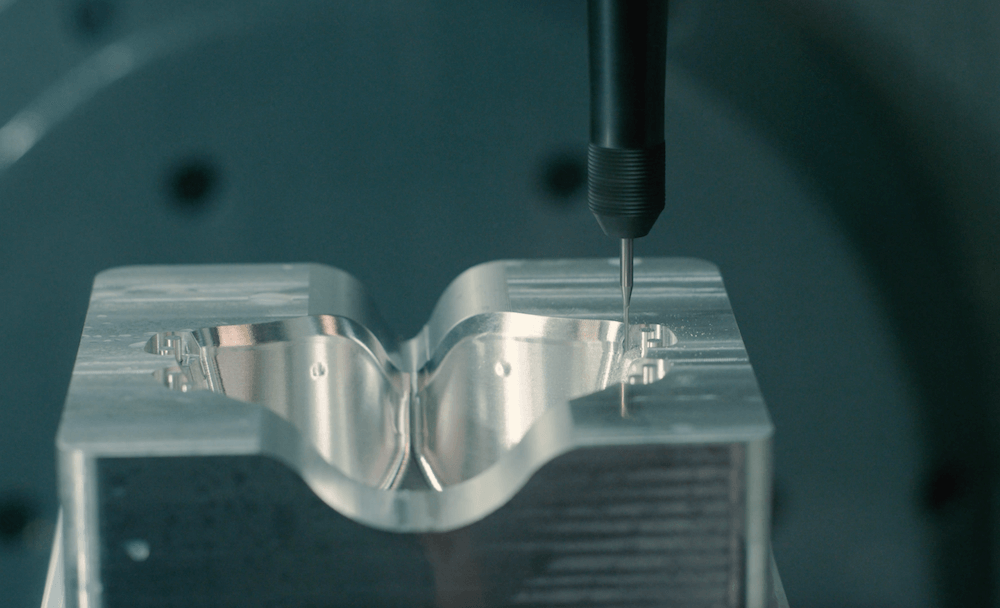

From Concept to Completion: A Step by Step Guide to Prototype Mold Fabrication

Prototyping is a critical step in product development, allowing product developers and engineers to create physical manifestations of product concepts and test them before committing to full-scale, expensive production molds. However, prototyping can be a major investment, requiring custom mold fabrication, material selection, process setting, and quality testing. For manufactured plastic and rubber parts, injection molding has become the most common method of producing prototypes due to its ability for rapid fabrication coupled with precision results. With the right approach to prototyping, product developers can gather critical product feedback, optimize designs, and minimize tooling rework down the line. This reduces

Navigating the Overmolding Process and Complex Prototyping Challenges

The plastic overmolding process is a specialized manufacturing technique that involves molding one material over another to create a single part. This technique often adds soft-touch surfaces on hard plastics, combines different materials for aesthetic appeal, or encapsulates metal components. Overmolding is used widely across various industries, including consumer electronics, automotive, medical devices, and more, enabling the creation of products that are not only functional but also ergonomic and visually appealing. By combining different materials, manufacturers can design products that meet specific performance criteria, enhance user experience, and comply with safety standards. For instance, overmolding can create a soft, rubber-like