Articles

Overcoming Challenges in Prototype Tooling for Injection Molding

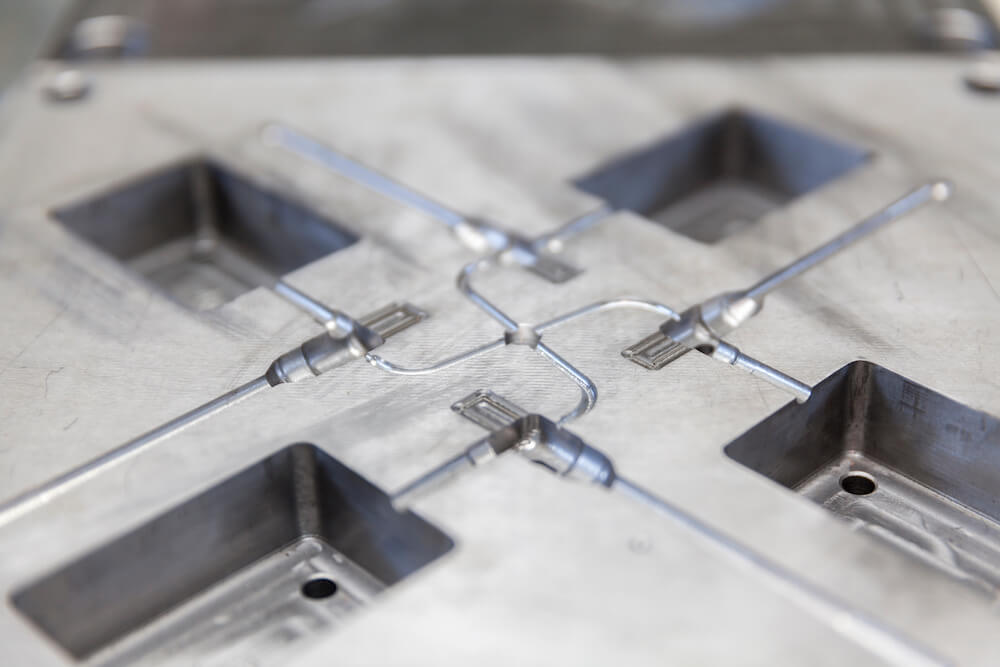

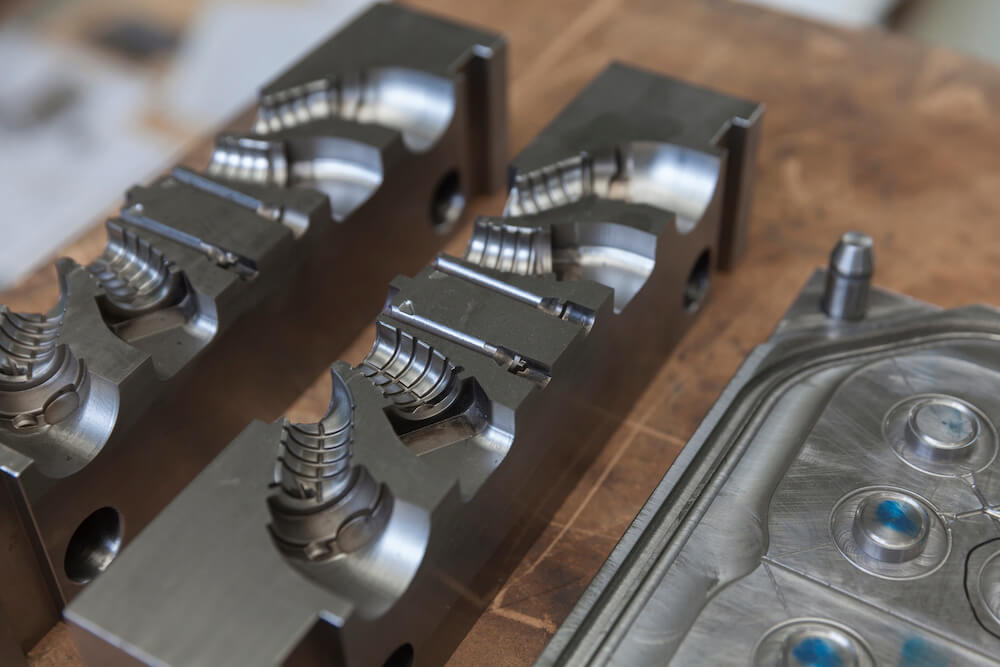

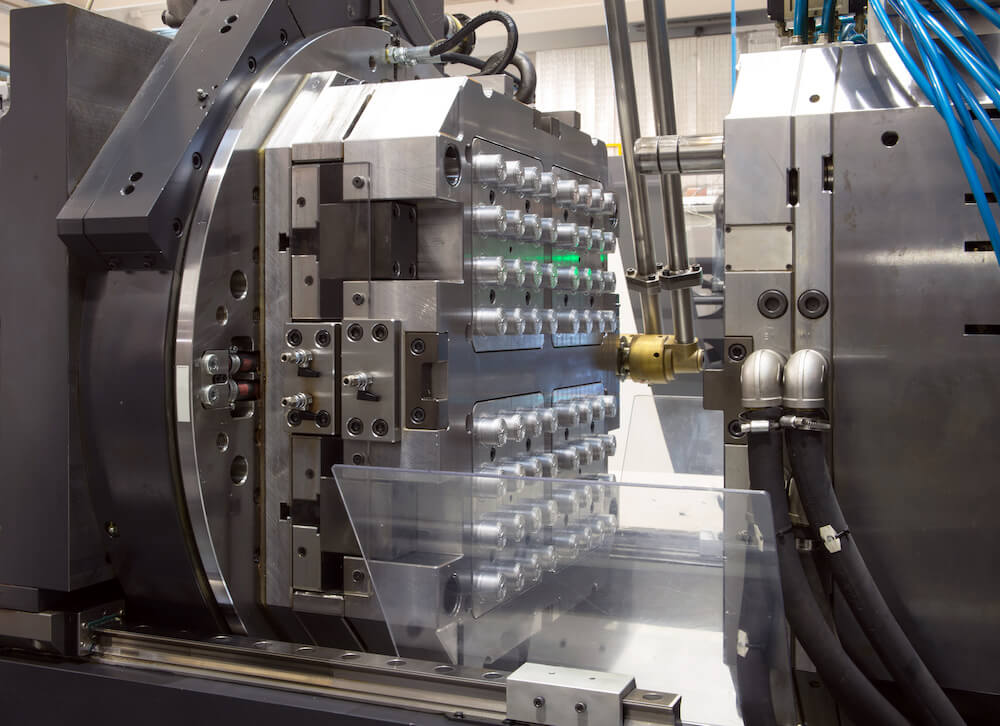

Injection molding is the primary manufacturing process for producing plastic parts across most industries. The process involves injecting molten plastic into a mold cavity, after which it cools and solidifies into the final part geometry. While full-scale production injection molds are meticulously engineered, less sophisticated prototype molds play an equally important role in bringing new plastic products to market. Prototype injection molds allow engineers to iterate on part designs, evaluate manufacturability, and validate critical features before committing to high-volume production tooling. However, prototype tooling brings its own set of distinct challenges. Compared to production tooling, prototype molds typically demand faster

ABS Plastic vs PLA: Considerations When Choosing Prototype Materials

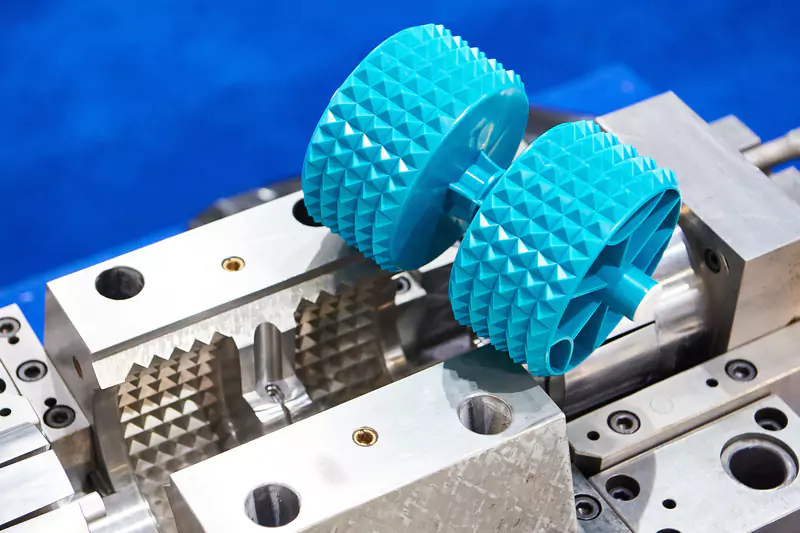

Selecting the appropriate materials for prototyping is crucial to represent the final product accurately. Prototyping enables designers and engineers to test concepts, refine designs, and validate functionality before moving to full-scale production. It’s essential to use materials that can endure prototyping demands while closely simulating the end product’s mechanical properties. Choosing the Right Material for Injection Molding Prototypes With various materials available for injection molding, choosing the right one is critical to creating effective prototypes. Acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) are commonly used plastics in injection molding prototypes. Each has unique advantages and disadvantages, making it important

Exploring How Prototype Tooling Offers a Smarter Alternative to Production Injection Molding Tooling with Cost-Efficient Strategies

Tooling strategy plays a critical role in product development and manufacturing processes. Choosing the right tooling approach is essential as products progress from initial concept to finished production. While production tooling is designed for mass manufacturing, prototype tooling offers a cost-efficient alternative for product development and early-stage development, so it often makes sense to include it in the project budget. Let’s explore the key differences between prototype and production tooling and the advantages of utilizing prototype tooling strategies to improve product development timelines. Understanding Prototype Tooling in Manufacturing Plastic injection molding tooling refers to molds used in manufacturing operations to

Prototype Injection Molding: Choosing the Right Material for Your Project

Prototyping is a critical step in the injection molding process for product design and development. Creating prototypes allows designers to test concepts, evaluate functionality, refine designs, and minimize risk before investing in production tooling. Prototype injection molding offers many benefits over other prototyping methods when it comes to simulating the actual injection molding process. Why Start With Prototype Injection Molding Prototype injection molding enables designers to: Prototype molding brings products to market faster and more efficiently by optimizing designs and processes early on. How Is Prototype Injection Molding Used Prototype injection molding can be used to create multiple versions of

What is Rapid Prototyping: Definition, Methods, and Advantages

Rapid prototyping has become an invaluable tool for companies looking to accelerate prototype development and quickly bring new products to market. In technology, manufacturing, and consumer goods, getting products to customers ahead of the competition is critical. By prototyping early in the process, companies can test and find design problems before full production. This early feedback allows for continuous refinement, as well as more robust and functional designs. Prototypes can be iterated faster, and get to market quicker and more efficiently. Leveraging rapid prototyping during the design phase can provide significant advantages. What is Rapid Prototyping? Rapid prototyping refers to

Production vs Plastic Prototype Molding – Understanding the Differences

Understanding the differences between prototype and production molding can be a game-changer in your product development process. Most think that to have production-equivalent plastic parts, you need to build an expensive, long lead-time, hardened-steel production mold and that this can only happen at the end of the product development process when the design is frozen and production-ready. This is simply not the case. Just like 3D printed parts have accelerated the product development process, so too can prototype plastic injection molding drastically improve speed to market, de-risk product failures, and speed up design iterations. Prototype injection molding has progressed. Such