Articles

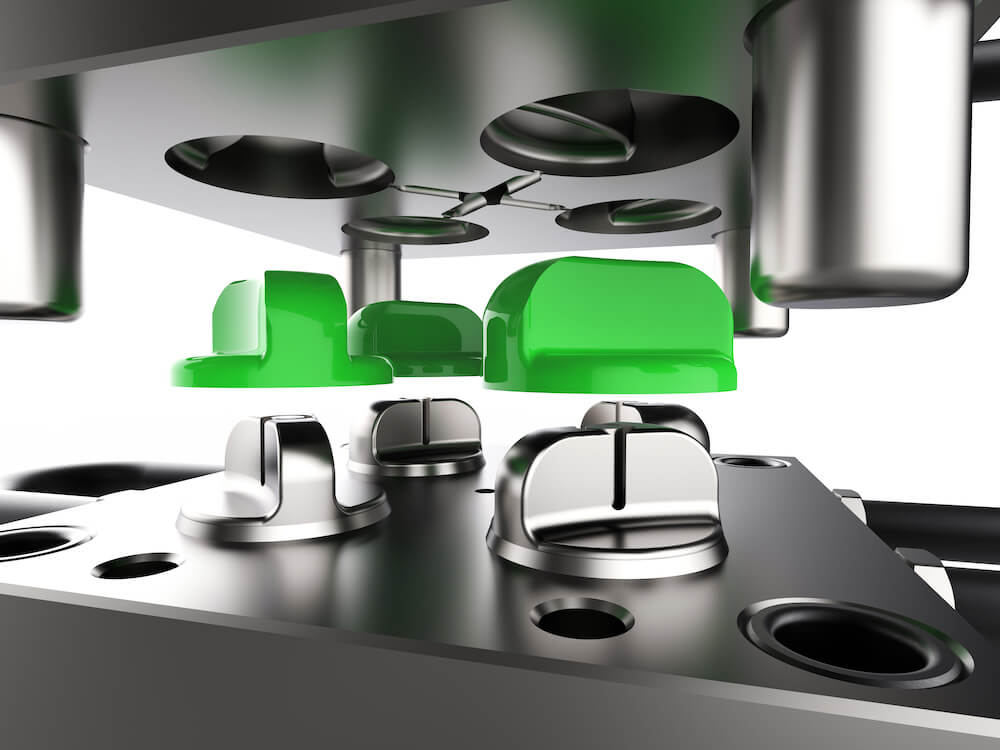

Prototype Injection Molding Process Guidelines

A Guide to Prototype Injection Molding Prototype injection molding is a manufacturing process that involves creating a physical plastic prototype or sample of a plastic product using injection molding techniques. It is a highly versatile and efficient method of producing small quantities of complex plastic parts with precision and speed. Prototype injection molding is widely used across various industries to streamline the product development process, reduce design risk, reduce time-to-market, and ensure the optimal design and performance of new products before investing in high-cost, multi-cavity production tooling. What are Prototypes? A prototype is a preliminary physical model of a new

Injection Molding Material Selection Guide: How Do I Specify the Right Plastic for My Product Application

There are over 60,000 different grades of plastics and growing each year. If you are developing a product that requires selection of a plastic, it can be quite a daunting task to determine the best plastic for your application among so many choices. This article shares the methods we use to help our clients with injection molding material selection. Searching an Online Injection Molding Material Database There are a few online material databases but the one that we use most often is a well-organized site called Matweb.com which details the properties of many materials including plastics, metals, ceramics, etc. While

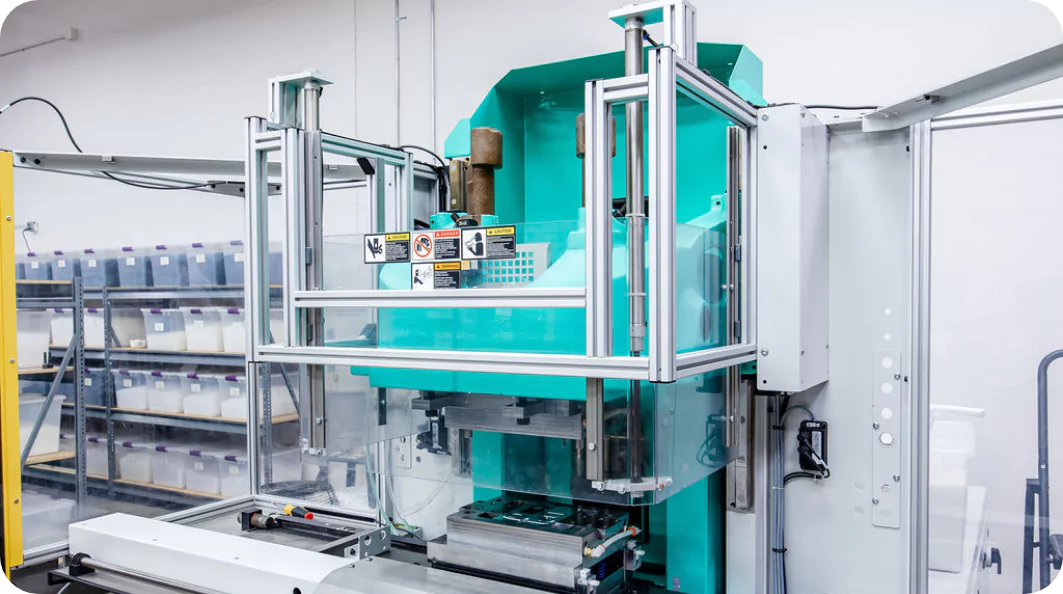

How Should I Prototype? Machined Parts, Print 3D Parts, or Fabricate a Prototype Mold

How should I prototype? Machined parts, print 3D parts, or fabricate a prototype mold Introduction Once a design engineer completes the first draft of their product design, the next step is to create a plan for how it will be fabricated, tested, and developed. There are three basic methods of prototype fabrication: 1) CNC machining, 2)

Plastic Part Manufacturing Costs

Plastics are a very good fit for manufacturing and their use becomes, even more, cost-effective as volume increases. Plastics are used to fabricate products in every major industry such as medical, automotive, electronics, housewares, etc due to their cost advantages. Besides cost, plastics are often used in high-volume manufacturing due to the consistency of parts and the wide range of mechanical properties available through plastic material selection. The purpose of this article is to inform you about how plastic part pricing is determined in manufacturing and how the number of cavities is driven by sales forecasts The Basic Economics of

10 Key Features to Look for in a Prototype Molder

If you are looking to hire a prototype molder there are several key features that you should look for as you compare molding partners that are critical to the success of your project.

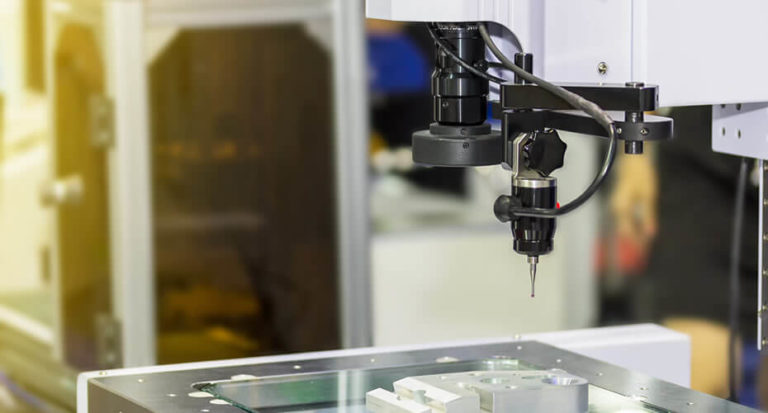

Which Factors Determine Molded Part Accuracy?

You may have wondered which factors determine molded part accuracy and therefore the tolerances of the injection molded parts from both prototype and production molders. It’s a complex question that I will try to explain. Some factors that are within the molder’s control and some are not. The following factors determine molded part accuracy during mold fabrication and molding