-

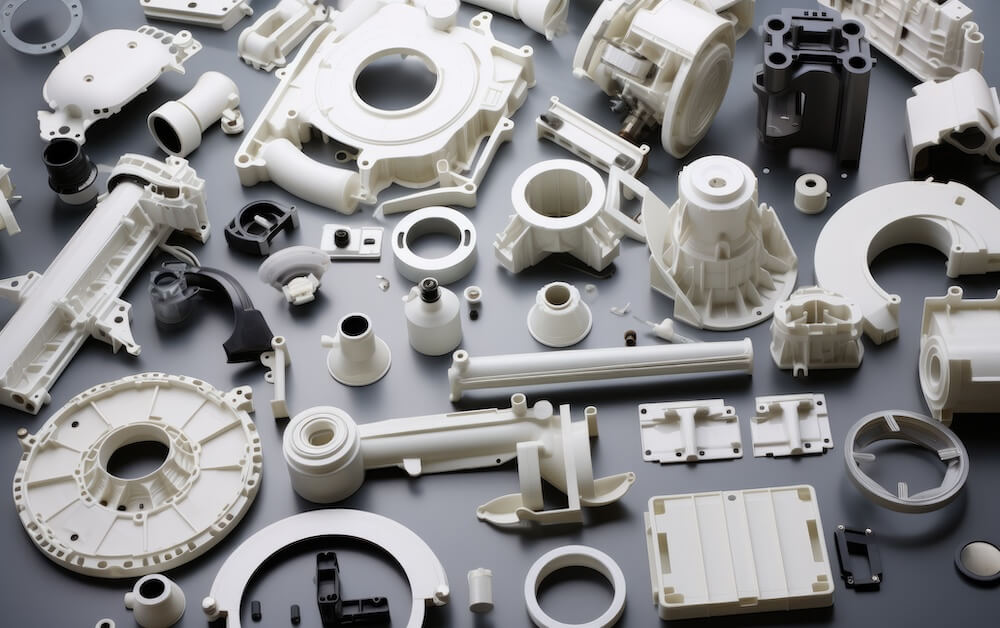

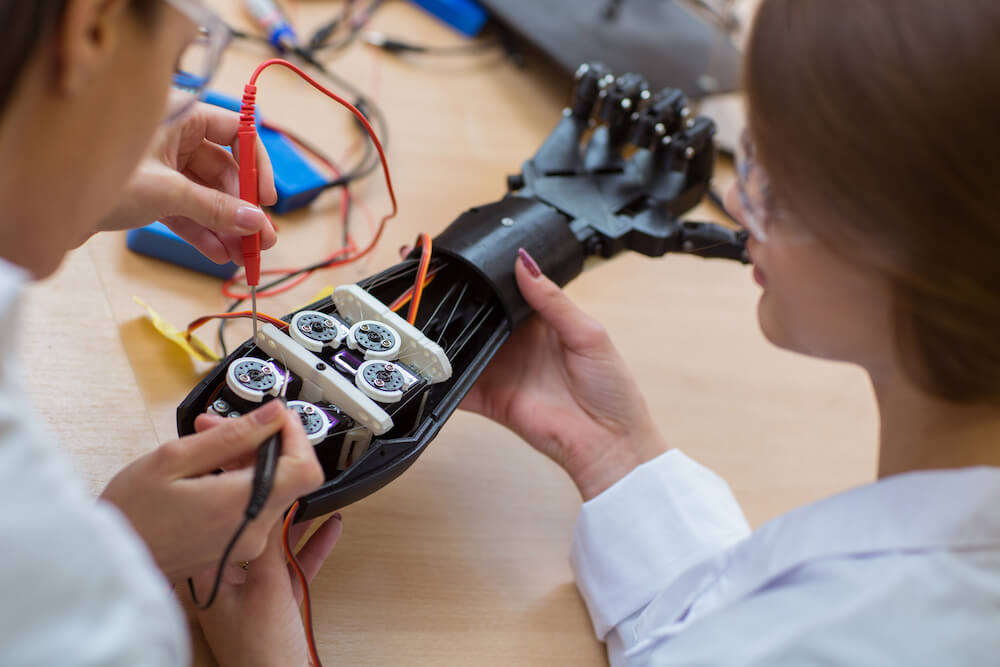

How to Effectively Communicate Your Plastic Product Idea to an Injection Molding Company for Prototyping

Effectively conveying your plastic prototype requirements to an injection molding company is essential for success. Our experts at Protoshop will walk you through the process in this guide, ensuring your vision is accurately translated into a high-quality prototype. Preparing Your Product Idea Before reaching out to an injection molding company, ...

READ MORE -

A Guide to Turning Your Plastic Product Idea into a Mass-Produced Product

Bringing a new plastic product idea to life can be exciting yet challenging. Taking an initial concept and transforming it into a tangible, mass-produced product involves creativity, strategic planning, and perseverance. While launching a successful new product is ultimately rewarding, it requires navigating many critical stages—from early design and prototyping ...

READ MORE -

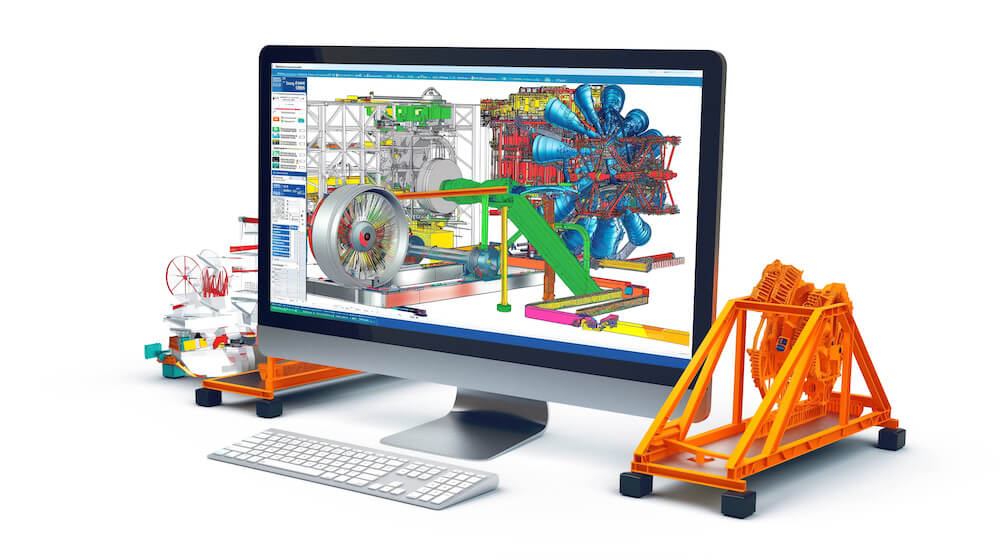

Incorporating DFM in Prototype Injection Molding

Prototype injection molding enables companies to quickly and cost-effectively produce low-volume plastic parts to test form, fit, and functionality before investing in full production tooling. However, many organizations fail to consider design for manufacturing (DFM) principles when developing prototypes. If DFM issues are only uncovered after the part is molded, ...

READ MORE -

Protoshop’s Dylann Ceriani Appeared on the “Being an Engineer” Podcast!

We’re excited to share a transcript from the Being an Engineer podcast featuring Dylann Ceriani, our co-founder and principal mechanical engineer at Protoshop. Dylann provides a compelling overview of her engineering journey, highlighting her expertise in prototype molding and the distinctions between prototype and production molding. She also delves into ...

READ MORE -

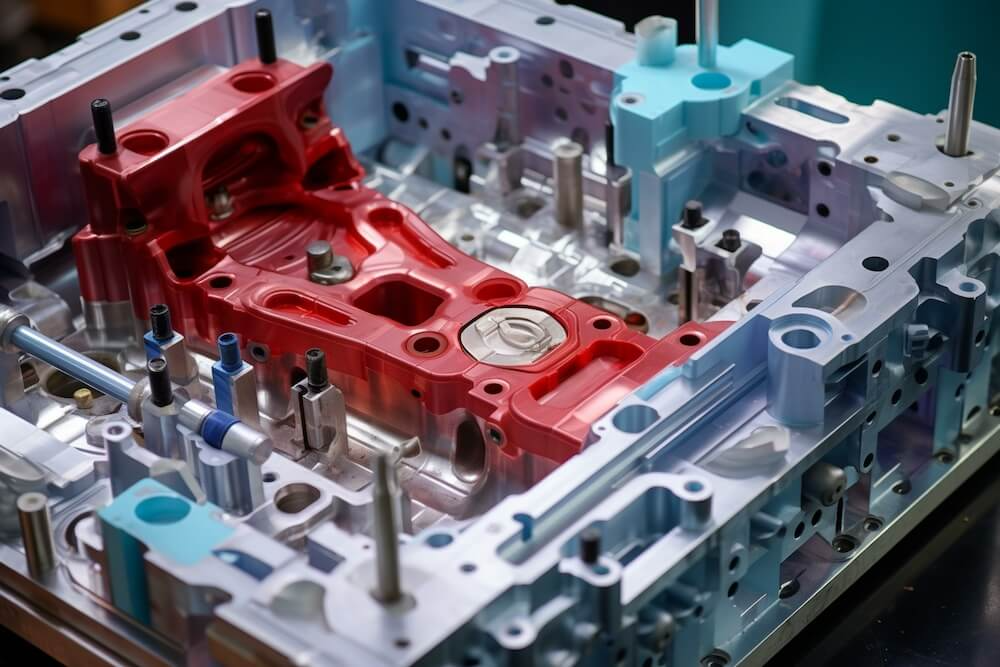

Aluminum Injection Mold Tool Life Expectancy: Factors Affecting Durability and Maintenance

Savvy businesses rely on rapidly produced prototype injection-molded parts to innovate and efficiently bring new products to market. While these molds can produce thousands of parts (even tens of thousands), they are not nearly as durable as production molds. Factors such as tooling material, design complexity, and maintenance practices affect ...

READ MORE -

Where Can I Get a Prototype Made? Accelerating Product Development with Protoshop’s Prototype Injection Molding Solutions

Developing prototypes is a pivotal phase in new product development. Prototype parts provide the first tangible models to evaluate ergonomic design attributes, conduct engineering tests to validate strength and function, refine specifications based on physical rather than virtual models, and gather direct customer feedback on potential products. Thorough evaluation at ...

READ MORE -

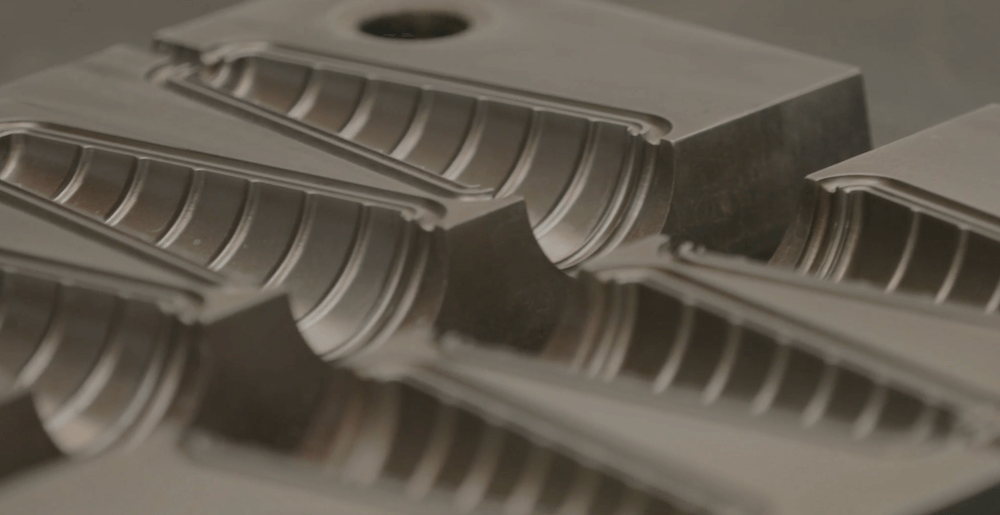

Speed vs. Quality in Prototype Tooling: Finding the Right Balance

Prototyping is one of the most important steps in the product development process. Prototypes allow product developers to find design flaws and/or test different design options quickly by providing tangible models that can be evaluated for form, fit, and functionality before committing to full-scale production tooling. Different types of prototypes ...

READ MORE -

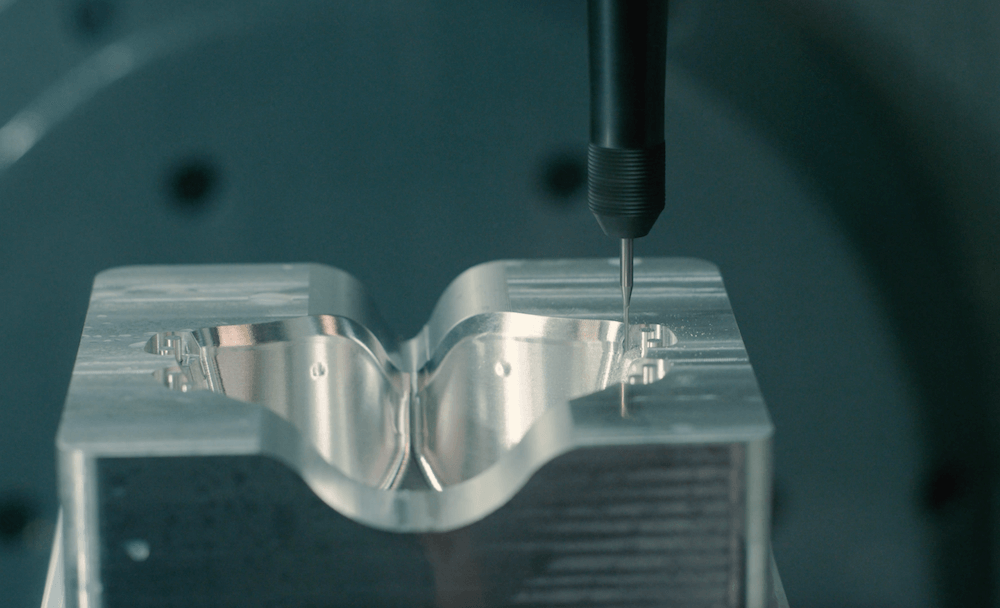

Cost-Effective Injection Mold Fabrication: Balancing Quality & Budget

The quality of an injection molding tool directly impacts product quality and overall production costs. Balancing the need for high-quality molds with budget constraints is a challenge product developers and manufacturers contend with continually. Strategies for achieving cost-effective mold fabrication without compromising quality will maximize the value of an injection ...

READ MORE -

Protoshop’s Dylann Ceriani on “The Selling Podcast” with Mike Williams and Scott Schlofman

On her guest appearance on The Selling Podcast, Dylann Ceriani, co-founder of Protoshop, chats with hosts Scott Schlofman and Mike Williams, providing a unique sales perspective from the standpoint of an engineer. Though Dylann loves technical work, she has stepped into sales out of necessity and devotion to her position ...

READ MORE -

Prototype Injection Molding for Product Designers: A Comprehensive Guide to Success

As the industry of product design evolves, innovation and efficiency have become more significant. Prototype injection molding offers designers flexibility, speed, and precision in bringing their concepts to life. In this comprehensive guide, we embark on a journey to understand prototype injection molding, equipping product designers with a robust toolkit ...

READ MORE