-

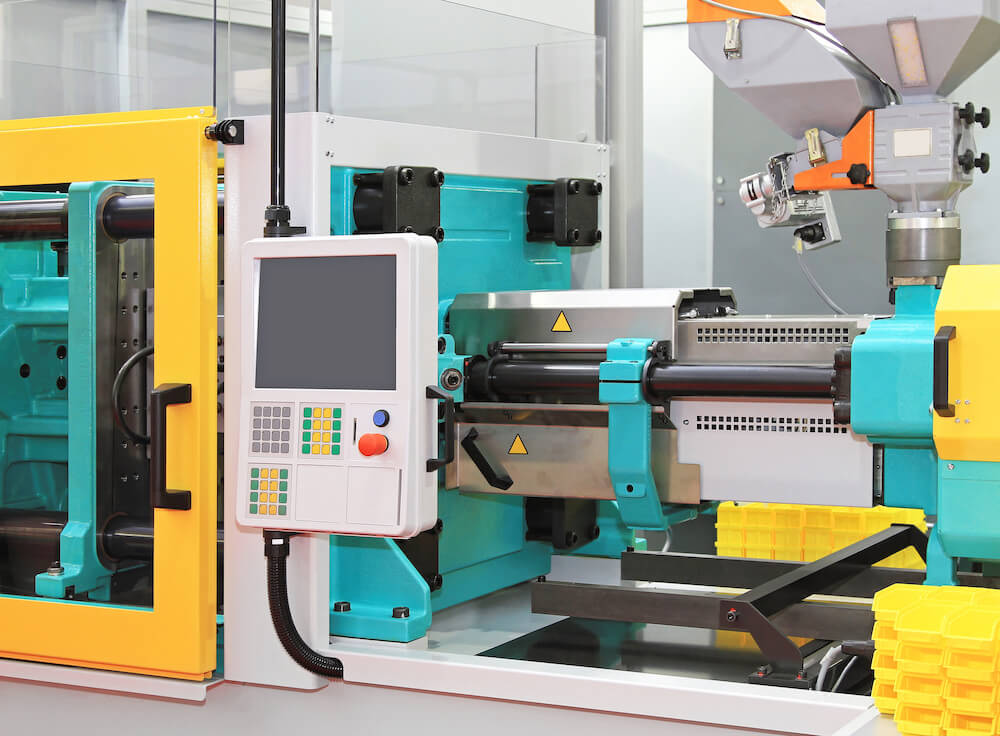

Comprehensive Breakdown of Plastic Injection Molding Machinery

Plastic injection molding is the most efficient and cost-effective way to produce plastic parts with complex geometries. The process involves injecting molten plastic material at high pressures into a mold cavity, which cools and hardens into the final part. From household items and consumer goods to medical devices and automotive ...

READ MORE -

Understanding Plastic Regrind in Injection Molding: Benefits and Applications

A popular method for achieving efficiency and reducing waste in plastic injection molding is the use of regrind. Below, we explore the plastic regrind process, its benefits, and important considerations to using these recycled materials. What is Regrind? Regrind typically refers to the practice of recycling plastic waste generated from ...

READ MORE -

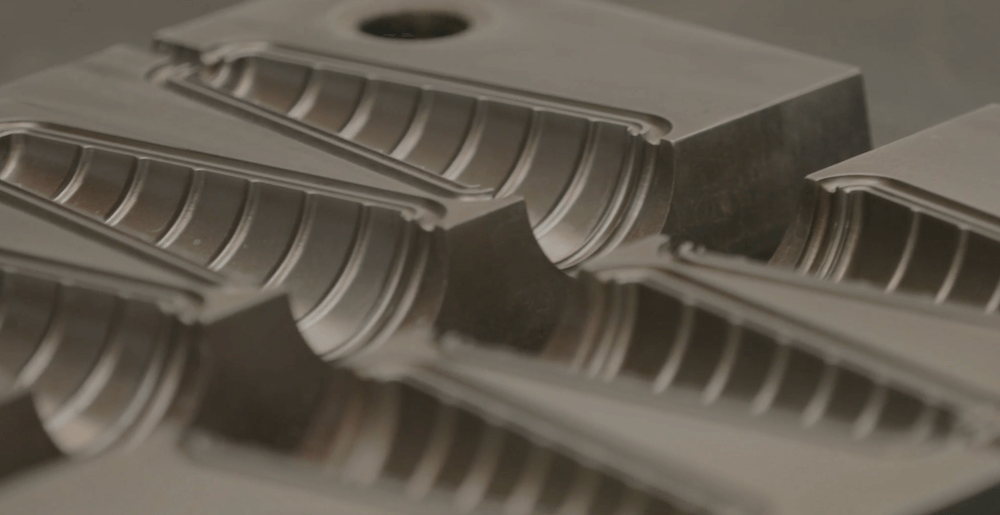

Designing Complex Injection Molding with Geometry for Prototyping: Core and Cavity Integration Strategies

Injection-molded parts are growing increasingly complex in design to meet demanding product requirements. Complex geometries with intricate features push the boundaries of mold technologies. Undercuts, thin walls, and unconventional shapes that would be impossible or impractical to mold using standard techniques are becoming more common. While complex designs allow products ...

READ MORE -

Customer-Centric Approach to Prototype Mold Fabrication

At Protoshop Inc., we pride ourselves on our customer-centric approach to prototype mold fabrication. As a leading provider of rapid prototype injection molding and prototype tooling services, we understand that our success is directly tied to the success of our customers. We prioritize personalized service and collaborative design processes, setting ...

READ MORE -

Incorporating DFM in Prototype Injection Molding

Prototype injection molding enables companies to quickly and cost-effectively produce low-volume plastic parts to test form, fit, and functionality before investing in full production tooling. However, many organizations fail to consider design for manufacturing (DFM) principles when developing prototypes. If DFM issues are only uncovered after the part is molded, ...

READ MORE -

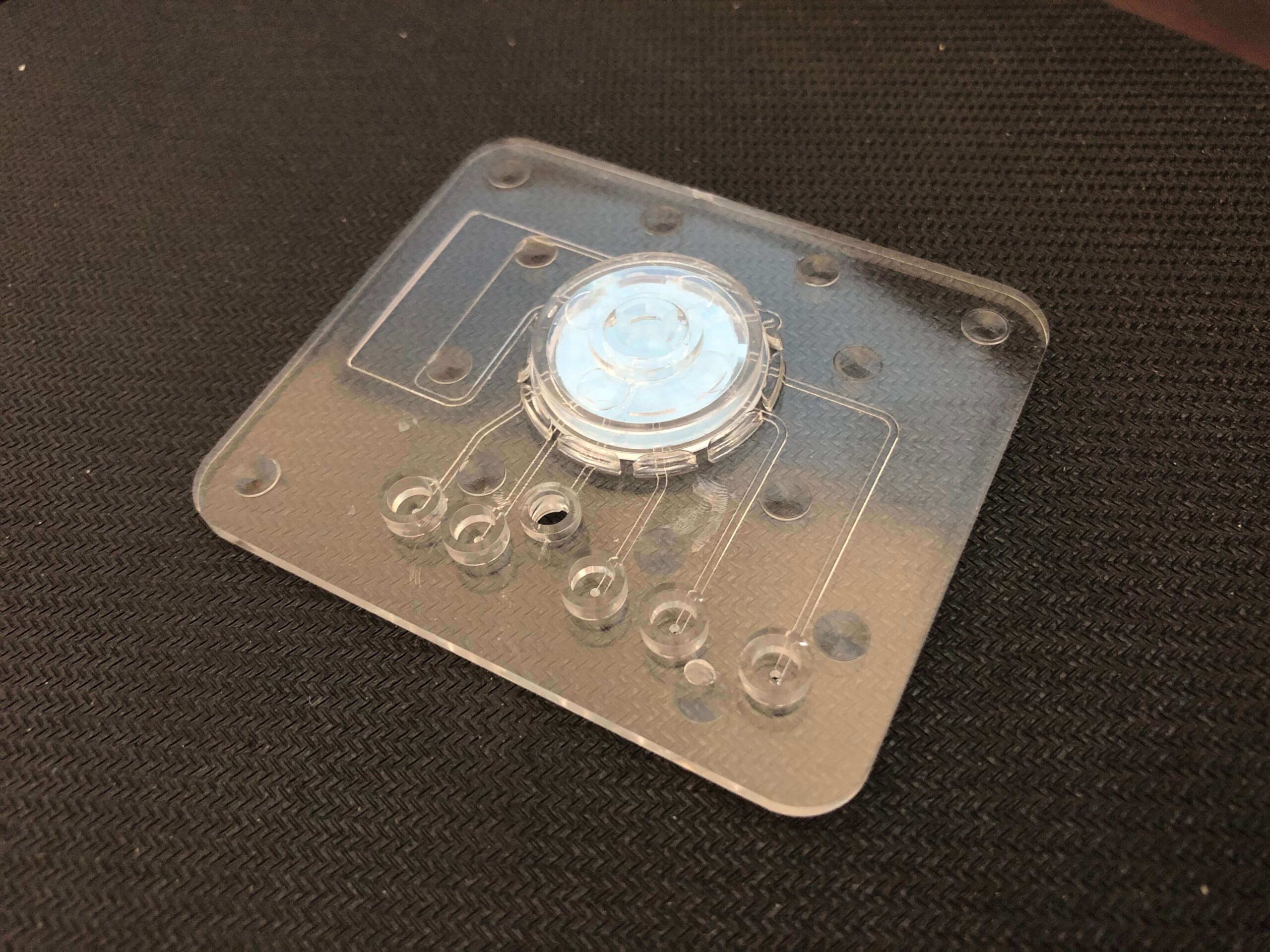

Prototype Injection Molding for Critical Function Testing

The Challenge Our customer was developing an In Vitro Diagnostic (IVD) cartridge that required assembling a valving component to the cartridge to control fluidic flow for the assay. Standard means for assembling these types of valves into disposable IVD cartridges includes fasteners, ultrasonic welding, laser welding, heat staking and other ...

READ MORE -

Where Can I Get a Prototype Made? Accelerating Product Development with Protoshop’s Prototype Injection Molding Solutions

Developing prototypes is a pivotal phase in new product development. Prototype parts provide the first tangible models to evaluate ergonomic design attributes, conduct engineering tests to validate strength and function, refine specifications based on physical rather than virtual models, and gather direct customer feedback on potential products. Thorough evaluation at ...

READ MORE -

Cost-Effective Injection Mold Fabrication: Balancing Quality & Budget

The quality of an injection molding tool directly impacts product quality and overall production costs. Balancing the need for high-quality molds with budget constraints is a challenge product developers and manufacturers contend with continually. Strategies for achieving cost-effective mold fabrication without compromising quality will maximize the value of an injection ...

READ MORE -

Prototype Injection Molding for Product Designers: A Comprehensive Guide to Success

As the industry of product design evolves, innovation and efficiency have become more significant. Prototype injection molding offers designers flexibility, speed, and precision in bringing their concepts to life. In this comprehensive guide, we embark on a journey to understand prototype injection molding, equipping product designers with a robust toolkit ...

READ MORE -

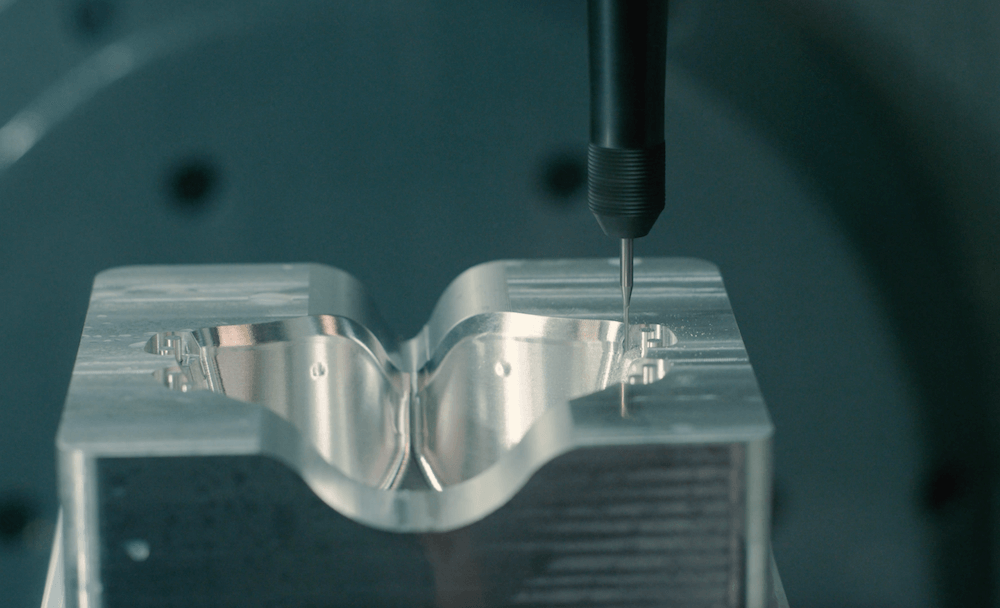

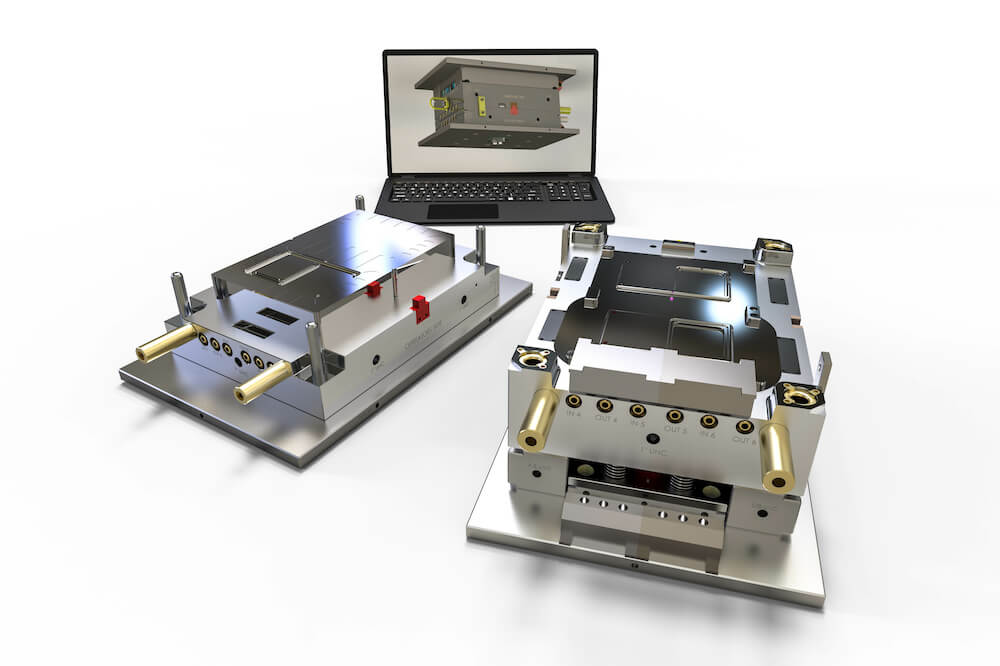

From Concept to Completion: A Step by Step Guide to Prototype Mold Fabrication

Prototyping is a critical step in product development, allowing product developers and engineers to create physical manifestations of product concepts and test them before committing to full-scale, expensive production molds. However, prototyping can be a major investment, requiring custom mold fabrication, material selection, process setting, and quality testing. For manufactured ...

READ MORE