-

ABS Plastic vs PLA: Choosing the Right Plastic for Your Prototype

Selecting the appropriate materials for prototyping is crucial to represent the final product accurately. Prototyping enables designers and engineers to test concepts, refine designs, and validate functionality before moving to full-scale production. It’s essential to use materials that can endure prototyping demands while closely simulating the end product’s mechanical properties. ...

READ MORE -

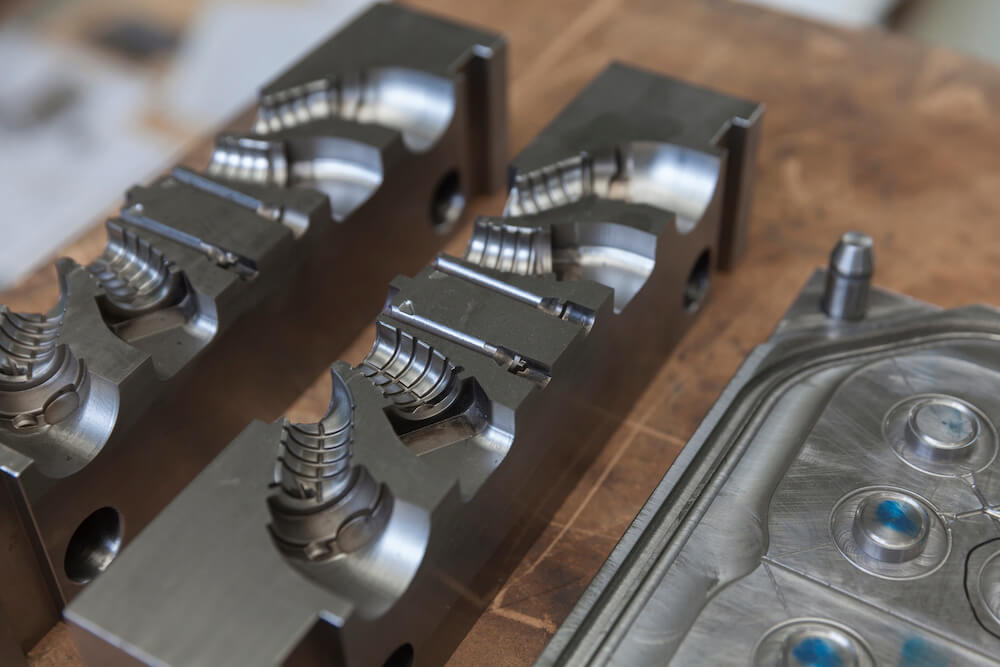

Exploring How Prototype Tooling Offers a Smarter Alternative to Production Injection Molding Tooling with Cost-Efficient Strategies

Tooling strategy plays a critical role in product development and manufacturing processes. Choosing the right tooling approach is essential as products progress from initial concept to finished production. While production tooling is designed for mass manufacturing, prototype tooling offers a cost-efficient alternative for product development and early-stage development, so it ...

READ MORE -

Prototype Injection Molding: Choosing the Right Material for Your Project

Prototyping is a critical step in the injection molding process for product design and development. Creating prototypes allows designers to test concepts, evaluate functionality, refine designs, and minimize risk before investing in production tooling. Prototype injection molding offers many benefits over other prototyping methods when it comes to simulating the ...

READ MORE -

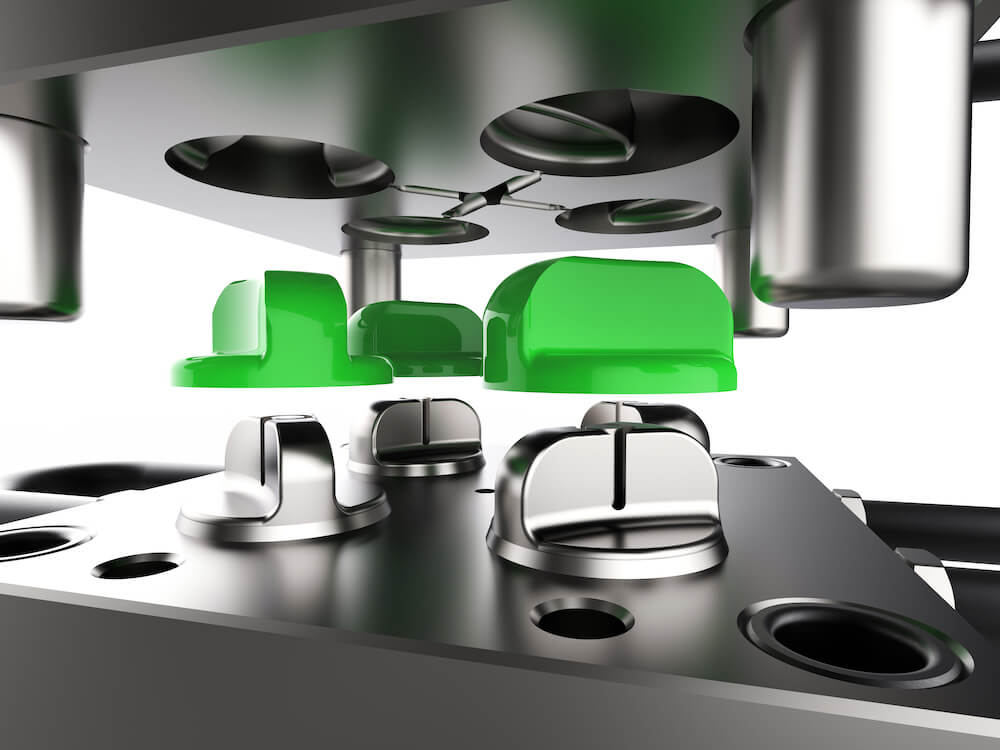

Production vs Plastic Prototype Molding – Understanding the Differences

Understanding the differences between prototype and production molding can be a game-changer in your product development process. Most think that to have production-equivalent plastic parts, you need to build an expensive, long lead-time, hardened-steel production mold and that this can only happen at the end of the product development process ...

READ MORE -

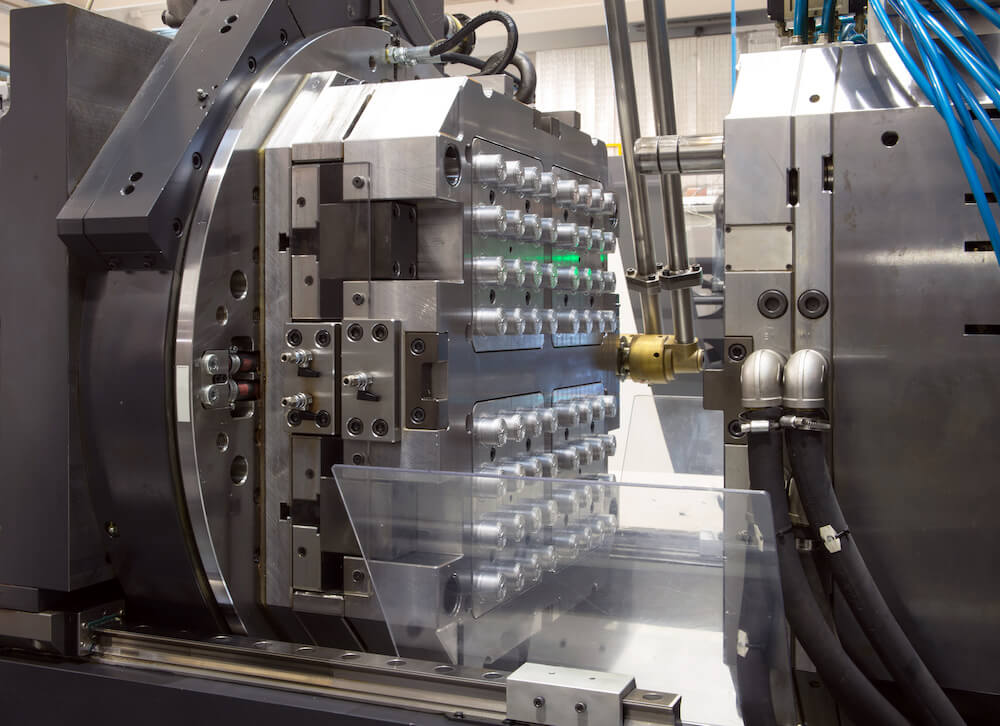

Prototype Injection Molding Process Guidelines

A Guide to Prototype Injection Molding Prototype injection molding is a manufacturing process that involves creating a physical plastic prototype or sample of a plastic product using injection molding techniques. It is a highly versatile and efficient method of producing small quantities of complex plastic parts with precision and speed. ...

READ MORE -

Injection Molding Material Selection Guide: How Do I Specify the Right Plastic for My Product Application

There are over 60,000 different grades of plastics and growing each year. If you are developing a product that requires selection of a plastic, it can be quite a daunting task to determine the best plastic for your application among so many choices. This article shares the methods we use ...

READ MORE -

Plastic Part Manufacturing Costs

Plastics are a very good fit for manufacturing and their use becomes, even more, cost-effective as volume increases. Plastics are used to fabricate products in every major industry such as medical, automotive, electronics, housewares, etc due to their cost advantages. Besides cost, plastics are often used in high-volume manufacturing due ...

READ MORE -

10 Key Features to Look for in a Prototype Molder

If you are looking to hire a prototype molder there are several key features that you should look for as you compare molding partners that are critical to the success of your project.

READ MORE -

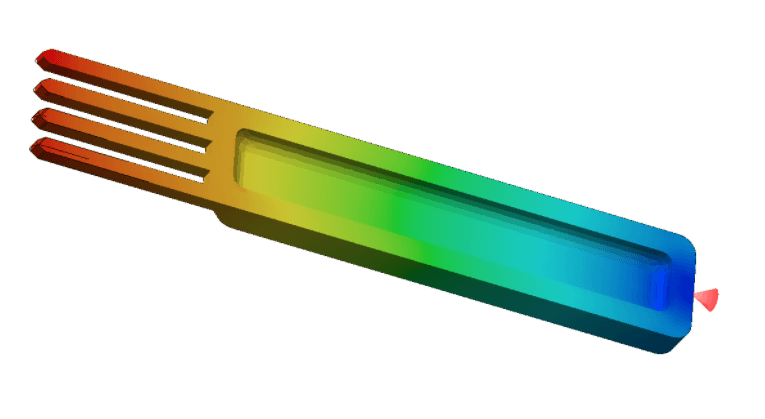

Micro Molding Requiring Material Specification And Simulation

A client approached us because they had not received acceptable parts with other prototype molding vendors. Issues included accuracy and surface finish of the 0.013” wide “teeth” features. We have extensive experience with micro-molding and molded similarly challenging features in the past, so we quoted mold fabrication and molding. There were three keys to success on this project: material selection, molding simulation and mold fabrication

READ MORE -

Which Factors Determine Molded Part Accuracy?

You may have wondered which factors determine molded part accuracy and therefore the tolerances of the injection molded parts from both prototype and production molders. It’s a complex question that I will try to explain. Some factors that are within the molder’s control and some are not. The following factors determine molded part accuracy during mold fabrication and molding

READ MORE